To compliment our Boat Wrap and U-DEK Boat Flooring products, Form A Sign are now an authorised Australia wide distributor of quality Lone Star Winches.

Lone Star Marine produce Australia’s very best winches and accessories that are made to perform, and last in the marine environment. Lone Star manufacture their boat winches in Australia. The collection includes several standard winch models in two different ranges as well as anchors and custom fitting accessories.

Products can be purchased through our

on-line shop. Each winch comes with DIY installation instructions. We ship Australia wide.

What is the best winch for my boat?

Your number one consideration is your boat’s rope and chain capacity. How much rope and chain do you need for your boat length, and what is your anchoring depth application? You can then pick your GX Series winch to suit.

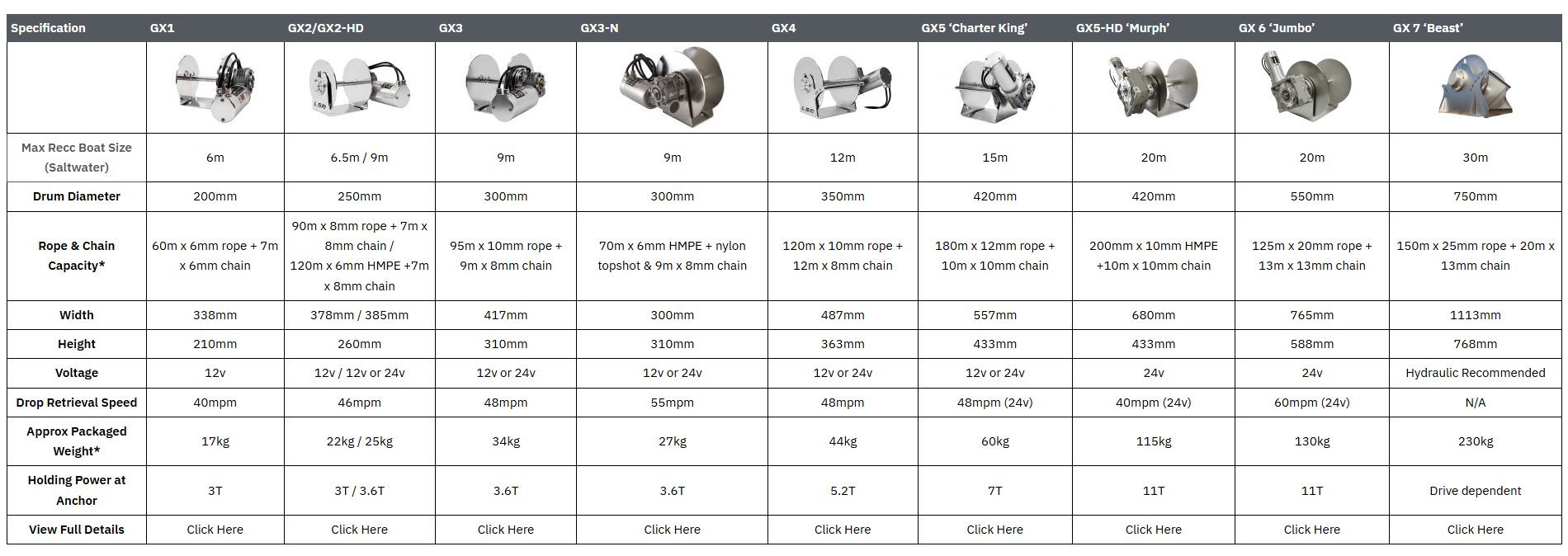

GX Series Winch Kits – Brushed Winches

GX Winch Kits are available in 3 combo kit configurations to suit a variety of vessels and anchoring depths.

Each combo kit includes the GX1 Winch Kit plus rope & chain, deck roller, chain guard, and anchor swivel.

DBN is double braid nylon, HS is HMPE hi strength rope. All HS kits include a nylon topshot for stretch.

Find Lone Star Marine GX Anchor Brushed Winch products on our on-line shop.

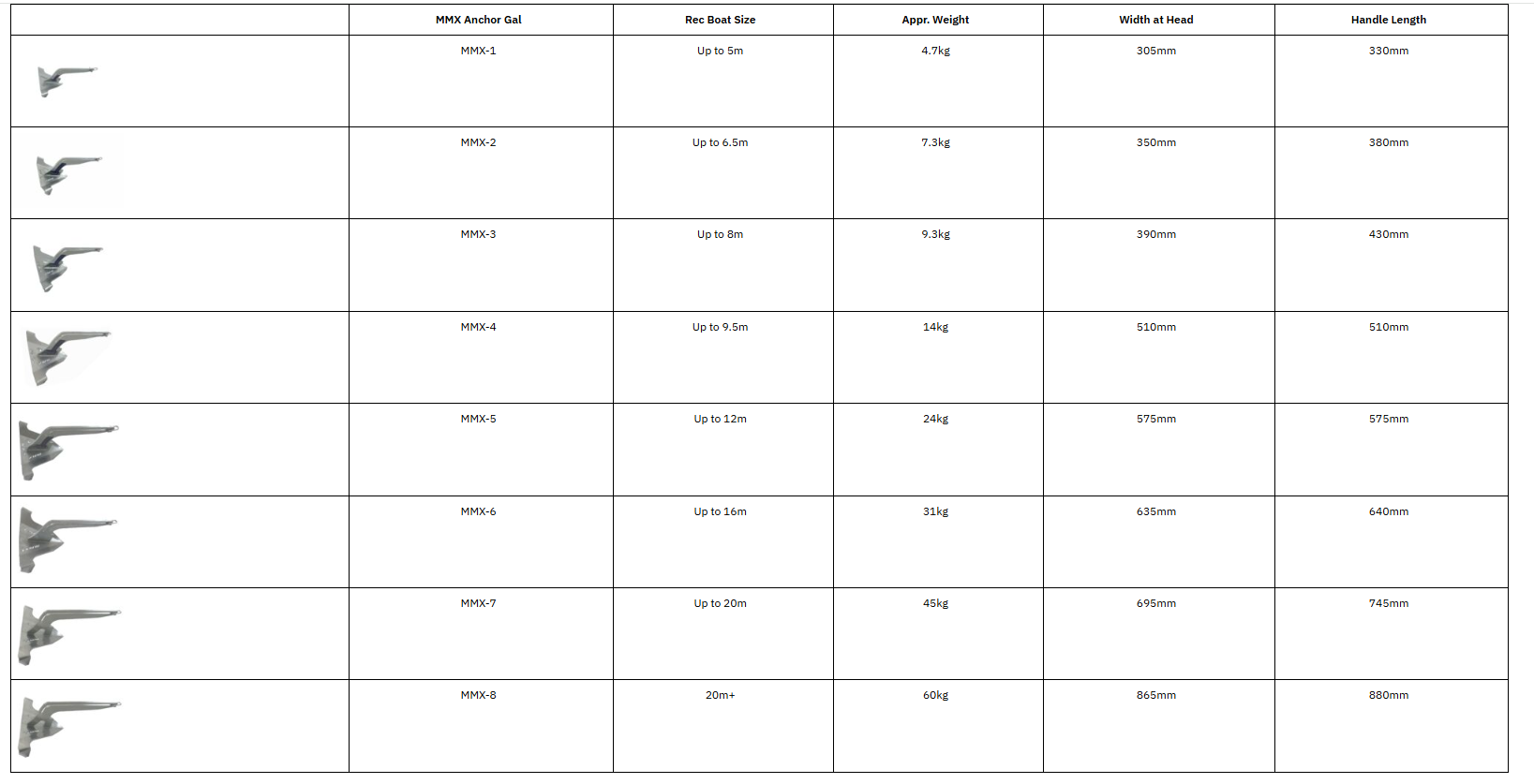

Which Anchor should I choose for my boat size or fishing conditions?

Lone Star Marine spent 16 months developing the MMX series of anchors. They were designed to tackle the worst in anchoring substrate, soft mud. The MMX Anchor is an anchor suitable for any seabed and any boat. The MMX anchor is designed to set fast and dig deep.

Featuring a lead free/hoop free design the MMX is Manufactured in Australia from High Tensile Steel Plate. The Lone Star Marine innovative retrieval slide drops all the way to the head for 170 degree retrieval in rock or reef. With a massive holding power to weight ratio, the MMX features minimum 8mm plate head construction (min. 10mm handle) for incredible strength, excellent balance, and displacement. Stabilizing wings and a folded drop tip design ensure excellent setting immediately and reduce the chance of the anchor breaking free in a tide change. All sizes avialable in hot dipped gal finish, MMX2, MMX3, MMX4 also available in 316 stainless steel.

The MMX anchor series will not disappoint.

• Fast Setting

• Lead Free

• Hoop Free

• Retrieval Slide

• High Holding Power

• Suitable for Most substrates

• Manufactured in Australia

• Lifetime Warranty Against Bending

Find Lone Star Marine MMX Anchor products on our on-line shop.

Do I need a bow sprit?

Depending on the placement of your anchor and winch, you may require a bow sprit. Bow sprits help anchors separate the distance between the boat and the anchor when it is retrieved so there is clearance.

Lone Star Marine’s CX range of bow sprits feature durable heavy gauge 316SS in a mirror like finish. With a wider opening, the CX range is suitable for almost any anchor and style. These are a static spirit with no hinge or moving parts and arefavored by commercial fishermen and those who are seeking ultra-tough anchoringaccessories, these spirits are meant to be used day in day out.

Rollers are made in durable HD with a 10 year UV life. The bolts are custommachined with a sleek button finish, a much better look than nyloc nuts and hexhead bolts.

CX series bow spirits are 100% Australian made with all extrusions, machining,stainless steel, and polishing all done in house at Lone Star Marine’s factory.

The CX series of bow sprits are available in 4 sizes for boats to 60ft + and anchors to 50kg.

How do you install your bow sprit? Check out some great advice from Lone Star Marine.

https://www.youtube.com/watch?v=LnCp1jC6wlAFind Lone Star Marine Anchor bow Sprit products on our on-line shop.

Does my boat anchor set up require a hawse pipe or deck roller?

Watch Lone Star Marine explain if you require a hawes pipe or deck roller. https://www.youtube.com/watch?v=txZovN-7Ic4

Hawes Pipe

If your anchor is mounted under the deck in

the anchor well, you will require a hawse pipe. This allows the rope and chain to feed into the winch, without damaging your boat or tangling.

Lone Star hawse pipes are:

• Ideal for applications where the winch is mounted close to the top deck

• Allows even rope & chain distribution across the drum

• Suitable for large drums close to the top deck

• Keeps the rain out of your boat

• Use instead of a deck roller

• Comes with 8 pre-made mounting holes

• Includes Mounting hardware

• High Polish 316 SS ConstructionSpecs

• Mounting Surface 100x225mm

• Overall Height 120mmFind Lone Star Marine Anchor Hawse pipe products on our on-line shop.

Does my boat anchor set up require a Deck Roller?

A Deck roller will help the feed of the line when you drop or retrieve your boat anchor.Lone Star’s CR Series Deluxe Deck Roller is a Stainless Steel roller with curved design for better Line lay and a higher capacity. The roller features an adjustable height pin to suit different Deck designs and custom installations.

- Available with 135mm or 195mm Roller

- Captive Design

- Adjustable Height

- High Polished 5mm 316SS Base (Australian Made)

- HD UV stabilized roller, extruded & machined in Australia

- Curved design for better line lay and capacity

- 2 predrilled countersunk mounting holes

- Includes mounting hardware

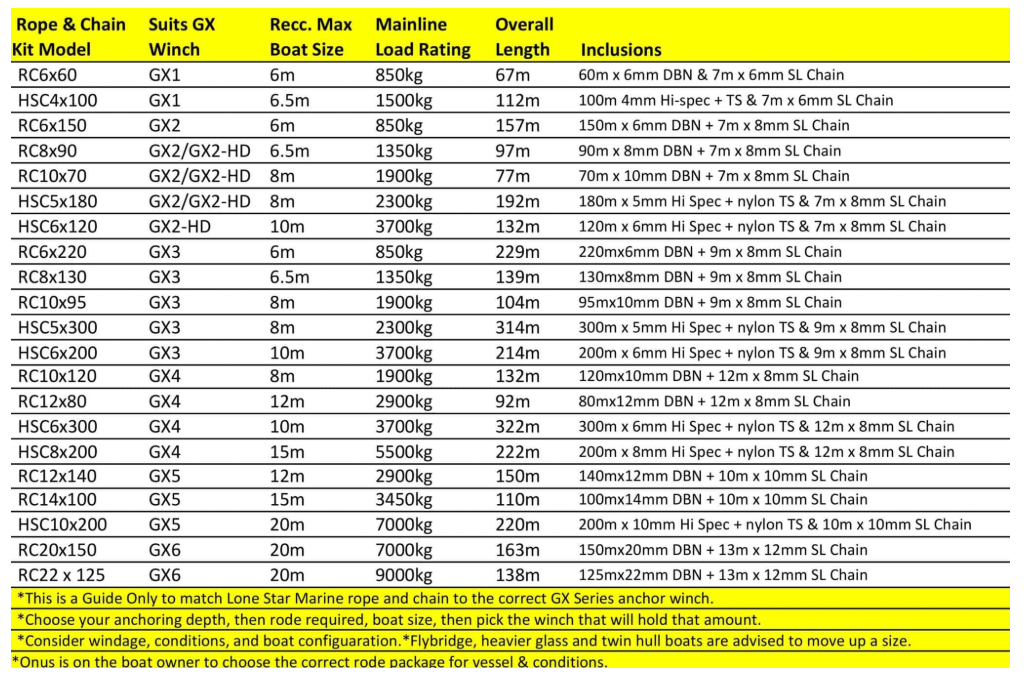

How much Rope and Chain do I need for my boat anchor?

Boat Anchor Chain Length

A good guide for boat anchor chain length is to use 1 and a half to two times the length of the boat. However, the heavier the boat, the more chain that is recommended. The purpose of the chain is to hold the anchor onto the floor of the ocean. So ideally a 7 meter boat would require 14 meters of chain. There is also a minimum of 10 meters of chain required.

Boat Anchor Rope Length

- Length: A general guideline for a standard anchor setup is 50 meters of rope, depending on the size of your craft, the depth of water you anchor in, and the wind conditions.

- Boat Size (Rope Length):Under 6m (20'): ~50m of rope. 6m – 8m (20'-26'): ~50m of rope. Over 8m (26'+): 60m or more.

You also need to ensure the drum on your Lone Star Anchor winch is large enough to fit the length of rope and chain you require for your conditions.

The table below explains the standard rope and chain lengths contained in the standard Lone Star Rope and Chain kits.

Which type of Boat Anchor rope should I use?

Lone Star Marine’s anchor rope is available in Double Braid Nylon or Hi Spec HMPE options.

The benefit of double braid nylon is that is has excellent stretch without damaging the ropes fibers. In the above table, RC indicates double braid nylon rope.

HMPE Hi Spec Rope is the same product used in 4WD winches. It is stronger than steel per diameter and goes a long way to adding extra length per given drum size. All HMPE rope kits come with a double braid nylon tops shot for stretch. HSC in the above table indicates HMPE line.

Boat anchor chain is available in 6, 8, 10, and 13mm short links. All of Lone Star Marine’s short link chains are Grade L and comply with the DIN766/A Standard sizing, it is burr free for a smooth finish.

All Lone Star Marine rope and chain kits include 316SS D-shackles.

Check out Lone Star Marine’s youtube guide on how to install your rope and chain.

http://youtube.com/watch?v=fN5LGGB5Vug

Find Lone Star Marine boat anchor chain guard on our on-line shop.

How do I install my Lone Star Marine boat anchor winch?

Check out some great advice from Lone Star Marine on how to Spool your GX Series Drum Anchor Winch with rope. https://www.youtube.com/watch?v=TRPVjePT4HM

How do you attach your anchor to your rope and chain? Lone Star Marine explains. https://www.youtube.com/watch?v=g4uk-WGqm3Q

Check out some great wiring tips for your GX Anchor from Lone Star Marine. https://www.youtube.com/watch?v=g4uk-WGqm3Q

What other useful accessories are available for my boat anchor winch setup?

Chain Guard

Fishing for timid fish like snapper or whiting? Lone Star Marine’s Chain Guard was developed to reduce the noise of chain going over the deck rollers and hawse pipes when you release or retrieve your boat anchor.

- Prevents scaring fish away by reducing noise

- Further prevents chain damage to your boat surfaces

- Long-lasting material (ticker and stiffer tight weave pattern)

- Comes in 8m, 10m and 12m lengths

- Suitable for 6mm and 8mm chain

Lone Star Marine demonstrates how to add chain guard to your boat anchor chain.https://www.youtube.com/watch?v=O61BlGPRNd8 Find Lone Star Marine boat anchor chain guard on our on-line shop.

Drum Anchor Winch Digital Line Counter

Lone Star Marine’s digital drum anchor line considers anchor drum width, diameter, shaft size, rope diameter, & overall rode length to produce extremely accurate depth readings. Simply enter the diameter and length of rope and chain on your drum and the DLC will take care of the rest.

https://www.youtube.com/watch?v=2yCihMyap_s

Find Lone Star Marine digital line counters on our on-line shop.

Lone Star Marine Downrigger

Want to get your bait down deep, where the large fish are?

https://www.youtube.com/watch?v=Wo5dyRT02oo

Ask us about the new product available from approximately April 2026.

Lone Star Marine’s DDW-250 Deep Drop and Down-Rigging features a brush less drive, variable speed, digital line counter, 1 piece frame, wider drag curve plus more….

- 316 Stainless Steel & Marine Grade 6061 T6 Marine Grade Anodised Aluminium Construction

- Solid 38mm Drive shafts suitable for extended heavy loads

- Brush-less drive with Variable Speed control

- Italian Made Transmissions

- Specialised for Deep Drop Fishing & Heavy Down-rigging

- Digital Line Counter can be set to meters, feet, or fathoms (AU preset to meters)

- Line proximity alarm

- Changeable throat depth on spool for Mono or Braided lines

- Braid Capacity 1500m x 200lb braid (with spool spacer)

- Mono Capacity 700m x 300lb mono (without spool spacer)

- 12 or 24v operation

- Up to 110m (375ft) per minute retrieval speed (12v)

- Up to 200m (680ft) per minute retrieval speed (24v)

- Fully Sealed for very low maintenance

- Very high efficiency, as little as 10 amps under light load

- Long Duty Cycle

- Smooth Powerful 2 stage drag can be set from very light to over 100KG

- No Drag side-load at higher settings

- No Cam adjustment

- No High Pitched reel noise

- 4 position gimbal mount

- Boom can be removed and stored when not in use

DDW-250 Combo Kit Includes:

- Complete Deep Drop Winch

- Rod Holder Mount

- 50 Amp MP Circuit Breaker

- Power plug + 5m twin core power lead (no Anderson plugs)

- 4 battery lugs & heatshrink

- Fibreglass Boom (DDW-250FG Combo) 316 Stainless Steel Boom (DDW-250SS Combo)

- LSM Closed Sheave with SS bearings• Bearing oil

- Cal’s drag grease

Your unit comes complete ready to fish deep drop or down-rig unit, all you need to supply is line.

Booms are available in either fibreglass or 316 stainless steel:

Fibreglass booms are made for reducing shock loads in swell or with larger fish and need to be used with larger 4-8kg weights.

Stainless Steel Boom Options are preferred by many commercial fishermen. They are also the better option when using the DDW as a down-rigger.

Find Lone Star Marine Downriggers on our on-line shop.

GX Series Boat Anchor Wireless Remote Control

Operate your anchor from anywhere within

your boat. Lone Star’s Marine Wireless

Remotes are suitable for all GX Anchor Winch makes and models (except Elite

Series) and will fit your current switching system & solenoid.

Package Includes

- 2 x Lone Star Wireless Remotes

Receiver

Lanyard - Terminal Screws for screw in solenoids

- Floating keychain

- Twin blade posts & female spades for blade solenoids Installation instructions & Diagrams

1 Year Warranty

Product Features

- Easy Anchor Deployment from anywhere on your boat!

- Operating Range of up to 100 ft

- Operate from the transom, bow, or fly bridge

- Easy installation

LSM Wireless Anchor Winch Controller Diagram

Find Lone Star Marine boat anchor wireless remote controls on our on-line shop.

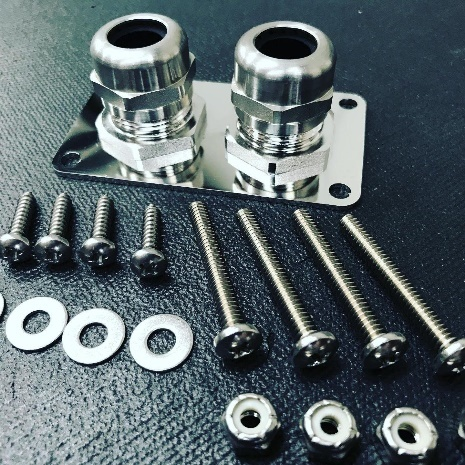

Gland Plate

Professionally mount your cables for your deck mounted boat anchor in a waterproof manner with Lone Star Marine’s AU Made 316 SS gland plate with waterproof glands.Fits cable size 16-35mm.

Find Lone Star Marine’s waterproof boat anchor mount accessories on our on-line shop.

How to install your Lone Star Winch

Step-by-Step Guide for Installing a Lone Star Anchor Winch on Your Boat

Form A Sign can recommend installers in Melbourne, or you can DIY the installation of your boat winch.

1. Tools and Materials Checklist:

- Lone Star Anchor Winch Kit: Ensure you have the complete anchor winch kit as available on the Form A Sign on-line shop, including the main winch unit, switch panel, circuit breaker, backing plate, and accompanying hardware.

- Drill: A power drill suitable for creating holes in the mounting surface as per the winch's installation instructions.

- Screwdrivers: Both flathead and Phillips-head screwdrivers of appropriate sizes for different fastening requirements during installation.

- Wrenches: Adjustable wrenches or socket wrenches to tighten and secure bolts and nuts. Ensure they fit the sizes specified by the winch's installation manual.

- Electrical Wiring and Connectors: High-quality electrical wiring suitable for marine use, matching the gauge recommended by the manufacturer. Connectors such as terminals, crimps, and heat-shrink tubing for secure electrical connections.

- Bolts, Nuts, and Washers: Assortment of bolts, nuts, and washers compatible with the winch's mounting requirements. Verify sizes and types specified in the installation manual.

- Sealant: Marine-grade sealant/adhesive recommended for sealing gaps and holes, preventing water intrusion, and enhancing the installation's durability.

- Appropriate Fasteners: Ensure you have the specific fasteners recommended by the manufacturer for securing the winch to the mounting surface. This may include stainless steel or galvanized hardware for corrosion resistance in marine environments.

Additional Recommended Tools:

- Tape Measure: For precise measurements and alignment.

- Marker/Pen: To mark drilling points accurately.

- Level: To ensure proper alignment during installation.

- Wire Cutters/Strippers: For preparing and trimming electrical wiring.

- Safety Equipment: Safety goggles, gloves, and appropriate personal protective equipment (PPE) for safe installation practices.

Before commencing the installation, double-check the Lone Star Anchor Winch manual provided with your purchase.

2. Select the Mounting Location:

Choose a suitable location on your boat for mounting the anchor winch. The Lone Star Anchor Winch typically offers three possible mounting positions on a boat:

- Deck Mount: This positioning involves mounting the winch on the deck of the boat, usually close to the bow. It's essential to ensure the deck is reinforced adequately to support the winch's weight and that the location doesn't obstruct other essential components.

- Below Deck Mount: This position involves installing the winch below deck, often in an anchor locker or a dedicated compartment. Ensure sufficient space for the winch's operation and adequate ventilation to prevent overheating. Additionally, verify easy access for maintenance and repairs.

- Bow Sprit Mount: Mounting the winch on a bow sprit involves affixing it to an extended structural component at the boat's bow. This positioning aids in keeping the anchor away from the boat's hull and minimizes potential damage. Ensure the bow sprit is sturdy and compatible with the winch's weight and operation.

For each mounting position, consider factors such as weight distribution, accessibility, interference with other boat elements, and reinforcement to guarantee a secure and functional installation. Always refer to the manufacturer's guidelines and, if uncertain, consult a professional for guidance.

3. Prepping the Mounting Surface:

- Clearing and Cleaning: Begin by thoroughly clearing the chosen mounting area. Remove any debris, remnants of previous installations, or objects that might obstruct the winch's placement or operation. Clean the surface meticulously to ensure a smooth and stable base for mounting.

- Assessing Structural Integrity: Inspect the mounting surface for its structural integrity. Check for any signs of weakness, cracks, or damage that might compromise the stability of the installation. Reinforce the area if necessary, utilizing appropriate materials or structural enhancements to fortify the surface and ensure it can withstand the winch's weight and movement.

- Surface Treatment: Consider surface treatment if applicable. Some materials may benefit from priming, sealing, or applying protective coatings to prevent corrosion, enhance durability, or provide additional support. Follow manufacturer recommendations or consult with professionals for specific surface treatments suitable for the mounting area.

- Securing the Foundation: Prior to mounting, ensure the area is dry and adequately prepared to accept the installation. Securing a solid foundation guarantees a stable and long-lasting attachment for the winch, reducing the risk of movement, vibration, or potential damage during its operation.

4. Position the Winch Accurately:

Positioning the Lone Star Anchor Winch accurately is pivotal for a successful installation:

- Placement: Carefully place the anchor winch on the designated mounting location, ensuring it aligns with the chosen spot on the boat's deck or below deck area.

- Marking Holes: Once positioned, mark the spots for drilling holes that will secure the winch in place. Use a marker or pen to clearly indicate the drilling points, ensuring they match the winch's designated mounting pattern.

- Alignment Verification: Before proceeding further, confirm the winch's alignment with the boat's structure. Ensure it sits level and doesn't interfere with other essential boat components, such as hatches, compartments, or rigging.

- Clearance Check: Verify that the winch's placement allows for unobstructed movement and operation. Ensure it doesn't hinder any access points or impede other functionalities on the boat.

- Consideration of Anchor Rode Path: Additionally, consider the path of the anchor rode (rope or chain) concerning the winch's positioning. Ensure a clear and unobstructed path for the anchor rode from the winch to the anchor locker or bow sprit, maintaining proper functionality during anchoring."

5. Drill Mounting Holes & Securely Attaching the Winch:

- Drilling Holes: With the marked spots as a guide, carefully drill holes into the mounting surface using an appropriately sized drill bit. Ensure the holes match the specified diameter and depth indicated in the Lone Star Anchor Winch's installation manual. It's crucial to maintain precision to accommodate the fasteners accurately.

- Ensuring Precision: Take care to drill the holes with precision, maintaining alignment and spacing according to the marked positions. Use a level to confirm that the drill is perpendicular to the surface for precise hole creation.

- Preparing for Fastening: After drilling, clean the holes to remove any debris or residual material, ensuring a smooth surface for the fasteners. Additionally, consider applying a sealant to the holes to prevent water intrusion and enhance the durability of the mounting points.

- Securing the Winch: Align the Lone Star Anchor Winch over the drilled holes and begin securing it in place. Utilize the supplied fasteners, usually bolts and nuts, to fasten the winch securely to the mounting location. Confirm that the fasteners match the recommended specifications in terms of size, material, and torque strength as per the manufacturer's instructions.

- Stable Installation: Tighten the fasteners evenly and securely, ensuring a stable and robust installation. Use appropriate tools like wrenches or socket wrenches to achieve the required torque without over-tightening, which could damage the mounting surface or the winch itself. Verify that the winch is firmly attached and doesn't exhibit any movement or looseness.

- Double-checking Stability: Once fastened, perform a final check to ensure the winch is firmly affixed to the mounting location. Gently test the winch for any unexpected movement or instability, confirming a secure and reliable attachment before proceeding with the next installation steps."

6. Connecting Electrical Wiring for the Anchor Winch:

- Power Source: Start by locating the appropriate power source for the anchor winch. Typically, this involves connecting to the boat's battery system, either the primary starting battery or a dedicated deep-cycle battery.

- Battery Selection: If using the primary starting battery, ensure its capacity aligns with the winch's power requirements and doesn't excessively drain the battery during anchor use. Alternatively, for frequent anchoring or larger vessels, a dedicated deep-cycle battery is recommended to avoid compromising the starting battery's performance.

- Wire Gauge and Length: Determine the correct wire gauge for the winch's power and ground wires based on the manufacturer's specifications. Use marine-grade tinned copper cables of appropriate length to reach from the winch location to the battery, allowing for some slack for installation flexibility.

- Circuit Protection: Install an appropriate fuse or circuit breaker near the battery's positive terminal to safeguard against electrical overloads and prevent damage to the winch or the boat's electrical system. Follow the manufacturer's recommendations for the correct fuse or breaker size based on the winch's power rating.

- Power and Ground Connections:Power Connection: Connect the winch's positive power wire to the positive terminal of the battery or the designated positive busbar, ensuring a secure and tight connection. Use appropriate terminals and connectors for a reliable and corrosion-resistant joint.Ground Connection: Connect the winch's negative or ground wire to the boat's grounding system or the negative terminal of the battery. Ensure a solid and clean connection, free from corrosion or loose fittings, to facilitate proper grounding and efficient electrical flow.

- Testing and Protection:Testing the Connection: Before finalizing the wiring, conduct a preliminary test to ensure the winch operates correctly. Test the winch's functions, such as raising and lowering the anchor, to verify proper electrical connectivity and functionality.Waterproofing and Insulation: Once confirmed, protect the electrical connections using marine-grade heat-shrink tubing or waterproof electrical tape to shield against moisture and corrosion. Additionally, route and secure the wiring away from potential hazards or areas prone to chafing to maintain its integrity.

- Final Checks and Safety Measures: After securing the wiring, perform a final inspection to ensure all connections are securely fastened, properly insulated, and routed safely. Double-check for any potential issues or loose connections before using the winch in actual anchoring operations. Regularly inspect the wiring and connections as part of routine boat maintenance to ensure continued reliability.

7. Route the Anchor Rode for Optimal Winch Operation:

- Selecting the Anchor Rode: Choose the appropriate anchor rode, whether it's a combination of rope and chain or solely rope, based on your boating needs and the recommendations outlined by the manufacturer. Ensure the rode's material and strength align with the winch's specifications for safe and efficient anchoring.

- Preparation and Securing: Prepare the selected anchor rode for threading through the winch's drum. If using a combination of rope and chain, securely attach the rope to the chain using suitable connectors or splicing methods, ensuring a reliable and secure union between the components.

- Threading the Anchor Rode: Carefully thread the anchor rode through the winch's drum according to the manufacturer's instructions. Start by feeding the rope or chain through the designated entry point on the winch, ensuring it follows the correct path guided by the winch's configuration.

- Proper Securing: As you thread the rode through the winch, maintain tension and guide it evenly onto the drum. Ensure the rope or chain is neatly spooled and doesn't overlap or tangle, as this can affect the winch's performance during anchor deployment and retrieval.

- Clear Pathway: Verify that the anchor rode's path remains unobstructed and free from any entanglements or obstacles. Check for any potential friction points or areas where the rode might snag during operation, ensuring a smooth and unimpeded pathway for the rode as it moves through the winch.

- Testing and Adjustment: After threading the rode, perform a trial run of the winch to test its functionality. Raise and lower the anchor to confirm that the rode operates smoothly and without any irregularities. Make any necessary adjustments to the routing or tensioning of the rode to ensure optimal performance.

- Regular Inspection: Regularly inspect the anchor rode and its pathway as part of routine maintenance. Check for signs of wear, fraying, or damage to the rode, and ensure it remains correctly routed and free from any potential hazards that could affect its functionality during anchoring operations."

8. Test the Winch's Functionality:

- Pre-Deployment Checks: Before the actual anchoring process, it's crucial to conduct comprehensive tests to ensure the Lone Star Anchor Winch functions as expected:

- Electrical Integrity: Begin by confirming the integrity of the electrical connections. Check all the wiring connections to the battery or power source, ensuring they are secure and properly insulated. Test the winch's control panel or switch for responsiveness, ensuring it initiates the winch's operation smoothly.

- Functional Testing: Activate the winch using the control mechanism to raise and lower the anchor (without actually deploying it into the water). Observe the winch's performance, ensuring it operates smoothly and without any unusual noises, hesitations, or jerky movements.

- Rope and Chain Alignment: While testing, pay attention to the alignment and movement of the anchor rode (rope or chain) as it spools or unspools from the winch drum. Confirm that the rode feeds onto the drum evenly and without tangling or overlapping.

- Anchoring Operation Simulation: Mimic anchoring scenarios by running the winch through various speeds and load conditions, simulating the actual anchoring process. Verify the winch's capability to handle different loads smoothly, ensuring it doesn't strain or exhibit any irregular behavior under varying conditions.

- Lowering and Raising: Test both the lowering and raising functions of the winch separately. Observe the winch's control over the anchor's descent and ascent, ensuring it provides precise and controlled movements without sudden drops or erratic motions.

- Monitoring and Adjustment: During the test, monitor the winch closely for any signs of overheating, unusual sounds, or vibrations. If any irregularities are detected, stop the test immediately and inspect the winch for potential issues. Make necessary adjustments or seek professional assistance if needed.

- Final Confirmation: Once satisfied with the winch's performance and operation during the test, power off the winch and verify that all components are in their correct positions. Ensure the winch is ready for actual anchoring operations and confidently deploy the anchor knowing that the winch is functioning as intended."

9. Secure Loose Cables:

Securing loose cables is pivotal to maintaining a tidy and hazard-free environment on your boat. Once the Lone Star Anchor Winch is installed and fully operational, take the time to gather any excess or dangling cables. Use cable ties, clamps, or cable management solutions to neatly bundle and fasten these wires, ensuring they're tucked away from moving parts or areas prone to water exposure. This preventive measure not only minimizes the risk of entanglement but also safeguards against potential damage caused by loose cables interfering with other crucial boat components during regular boating activities.

10. Perform Operational Checks:

Before setting sail or using the anchor winch in real anchoring scenarios, conducting a thorough operational check is essential. Take a moment to meticulously inspect all the connections, from the electrical wiring to the battery terminals, ensuring they're snug, corrosion-free, and properly insulated. Verify the tightness of the mounting hardware, confirming that the winch is securely affixed to the boat's surface without any loose fittings. Engage the winch controls to validate its functionality once again, testing both the raising and lowering operations to guarantee a smooth and responsive performance. This final inspection serves as a last checkpoint, ensuring the Lone Star Anchor Winch is primed and ready for dependable operation when needed on your boating adventures.

11. Prioritize Safety Measures:

Always adhere to safety precautions during anchor winch use, and make sure you and your crew are well-versed in its operation for safe and efficient anchoring.

For specific instructions and guidelines tailored to your Lone Star Anchor Winch model, consult the installation pdf. If you're uncertain about any step, consider get in touch with Boat Hardware or Lone Star Marin to ensure a secure and reliable installation.

Questions? We're here to help!

Reach out to Form A Sign with any questions, our Lone Star Boat Winch expert is here to help.

Check out the videos below for helpful demonstrations, tips and tricks from expert Malki at Lone Star Marine.