Marine Boat Flooring

Form A Sign has a unique partnership with Ultralon Foam Group to offer you a superior quality, cost effective, non-slip EVA boat floor deck solution. Our boat deck flooring improves underfoot comfort and safety whilst increasing the protection of your boat. Best of all our boat floors are easy to clean.

When only the best marine flooring will do

Being competition fishermen, Form A Sign know that your boat must perform every time. That’s why we have partnered with the leading global manufacturer of boat flooring as the distributor for Victoria. U-DEK is designed and produced by Ultralon Foam International, a leading global manufacturer of PE and EVA foam, using its own dedicated plant and IP. Tightly controlled manufacturing processes, careful selection of raw materials from the rubber plantations in Vietnam and 3M marine grade adhesives, high level technical expertise and the latest technology and equipment, enable the company to offer customers quality, reliability and consistency of product. Our boat decking products or boat decking materials are the best boat carpet material available.

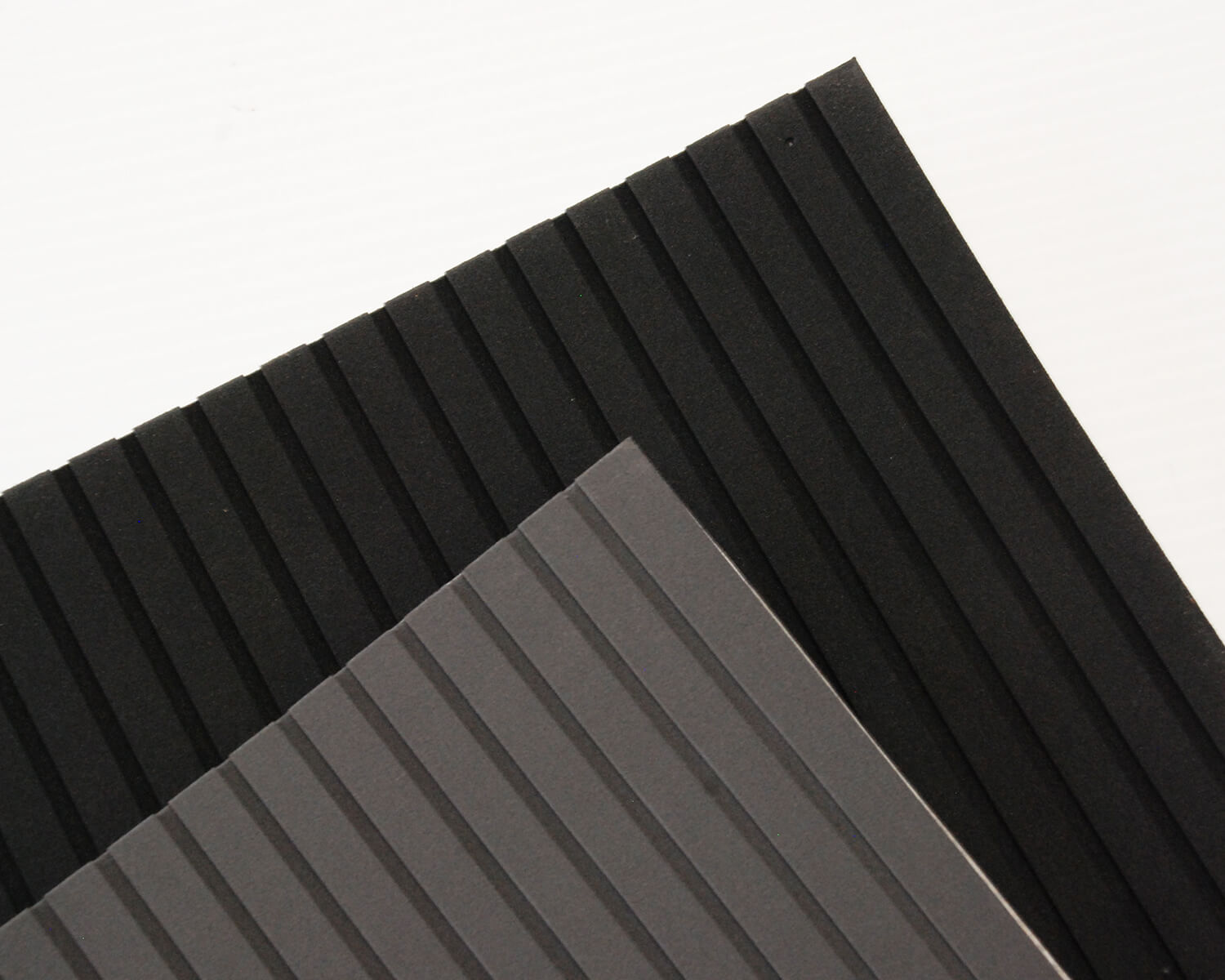

Ultralon closed-cell chemically cross-linked foams are manufactured in Vietnam from polyethylene (PE), ethylene-vinyl acetate copolymers (EVA) or a high-tech blended copolymer. The fine cell structure gives minimal water absorption, a high buoyancy rating and excellent chemical resistance. No chlorofluorocarbon (CFC) product or derivatives are used, and no organic fillers are added to foams. Less chemical fillers means the EVA remains cool underfoot.

U-DEK marine decking is a great looking and high performing durable, comfortable, easy to clean and non-slip boat floor covering option for all types of marine craft, from sailing yachts, motor yachts, trailer boats, to RIBS and personal watercraft. Just like our 3M™ boat wrapping materials, the Ultralon U-DEK boat floor material is made to last in the harsh marine environment.

U-DEK Boat Flooring

U-DEK is made from lightweight closed cell foam, offering a high level of comfort underfoot and excellent traction in all conditions. Durable and low maintenance, U-DEK is supplied in various colours and tread options to suit individual styles. U-DEK boat floor decking comes with a 3M™ acrylic based high-bond pressure sensitive and durable adhesive.

Form A Sign’s custom marine boat deck treads reduce noise in your hull, are shock absorbing, anti-slip and UV stable for 5-7 years. U-DEK boat flooring also doesn’t absorb water and is easy to clean with water. You can wash any bait or fish residue straight off your boat floor.

Form A Sign only offers Ultralon’s newest and best boat flooring product. New U-DEK 190 has a higher density than the previous 140 model, which leads to increased durability, lower susceptibility to light amplification, improved heat tolerance and less shrinkage. The increased tensile and tear strength and higher shear elongation means U-DEK 190 is one of the highest performing foams available for your customers’ decks.

To manufacture, design and install U-DEK custom boat flooring, we have your boat for about 8-10 days in our Noble Park North factory. We template with our Prodim digital templater, neaten up the lines in the computer, produce a paper pounce to check the fit, then design your artwork, proof your design, manufacture and install. for larger boats that can't come to us on a trailer, we offer an on-site templating service, or can talk you through our remote templating process.

personalise your boat floor

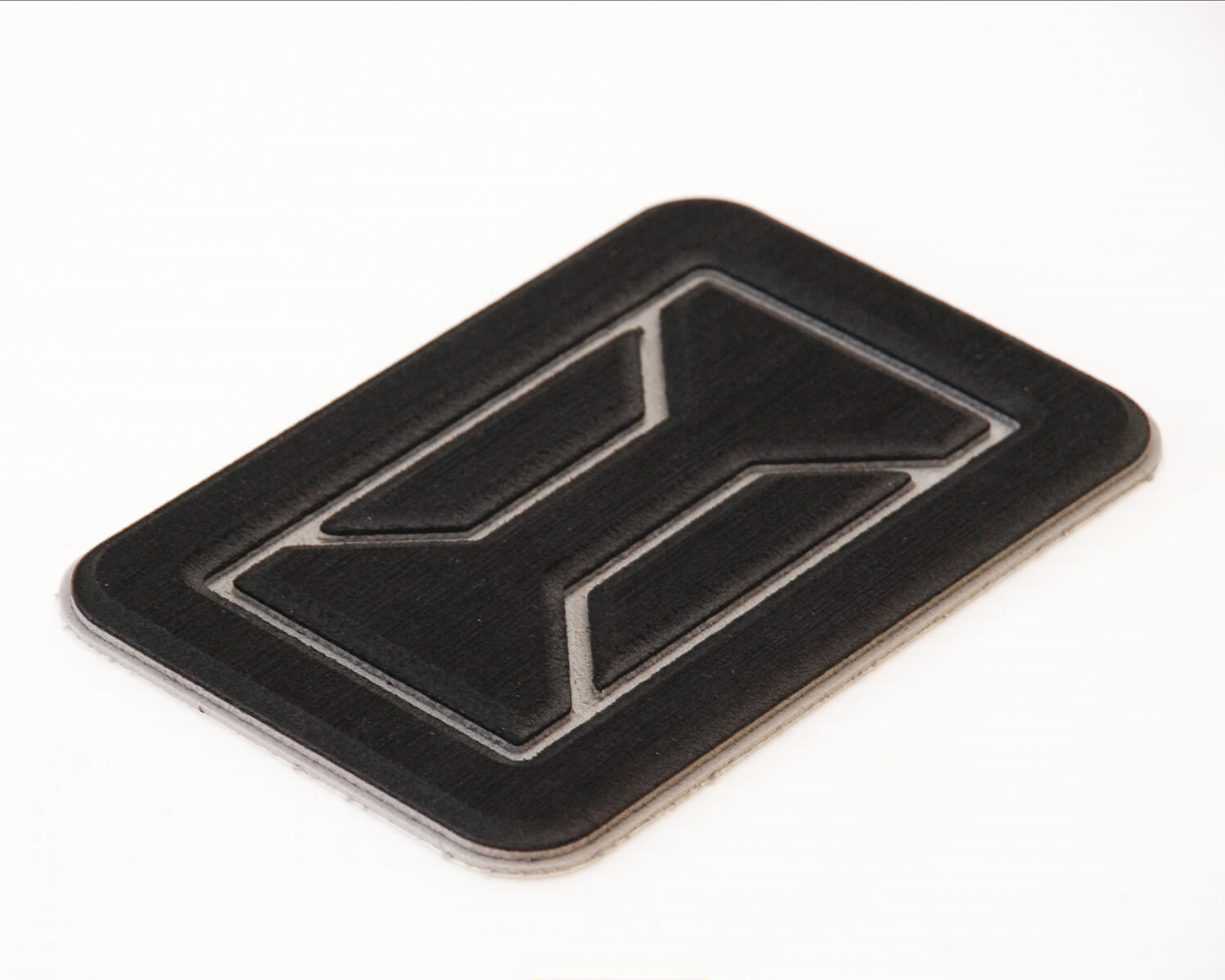

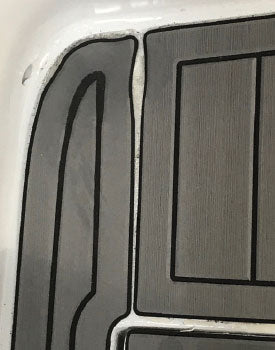

U-DEK Laminated is a dual layer foam decking. Utilising our CNC Router and Summa Cutter we are able to create the tradition teak plank-look, as well as custom logos and shapes in your boat deck tread. CNC routering cuts through the top layer of foam exposing the second colour underneath. Creating impressive durable boat floors.

We also offer DIY Boat Flooring ... Nano, Z tread, Octi Tread, 3mm Brushed U-DEK or pre-routed 6mm U-DEK

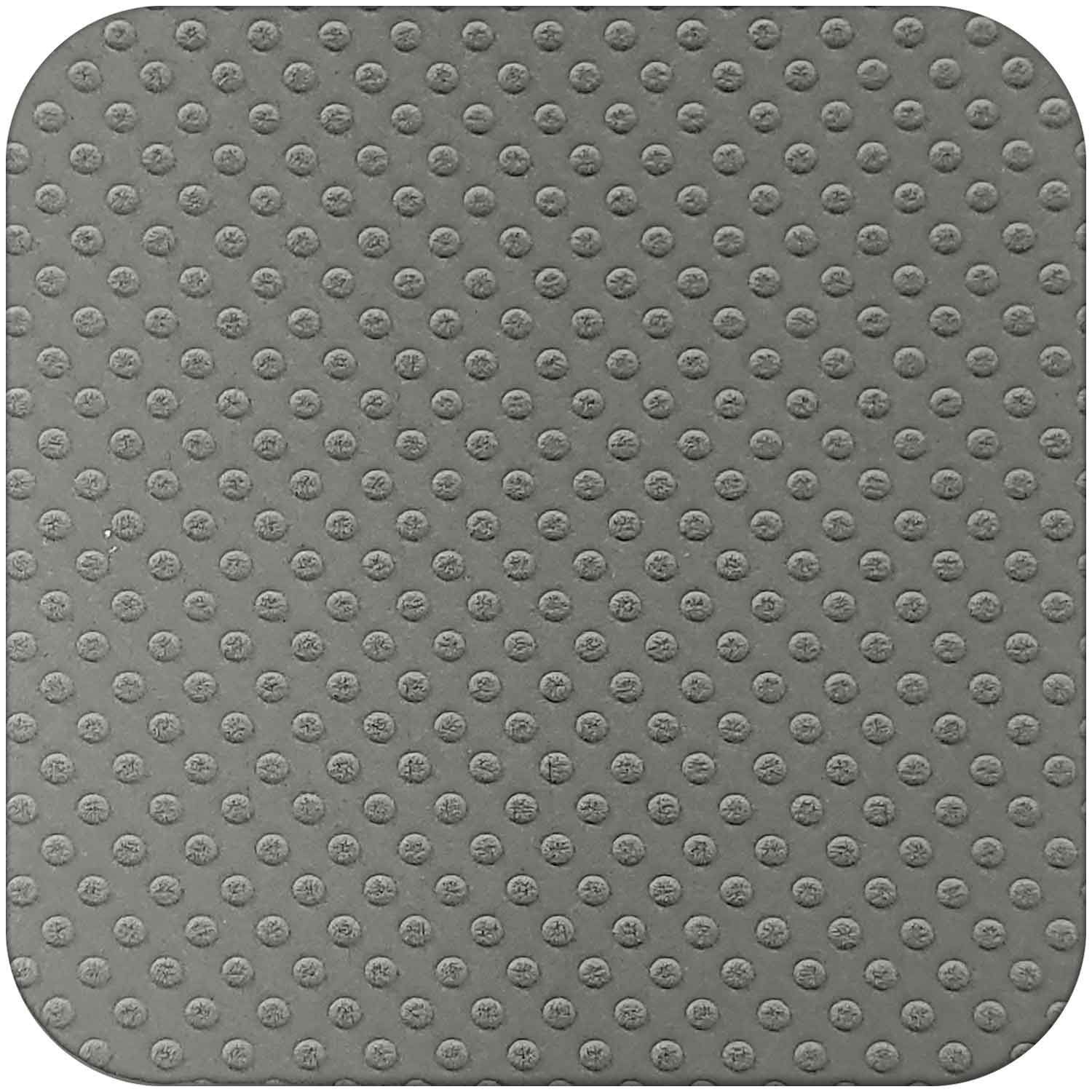

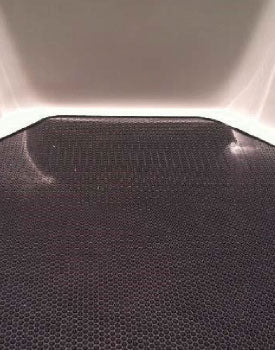

Nano-DOT™ is a quality boat flooring that is used by professional fishermen and will last in the marine environment.

Nano-DOT™ anti-slip marine deck tread has a unique pressed dot pattern with a buff finish is, and like all Ultralon decking solutions, durable and easy to maintain. Nano-DOT™ is soft and cushioning underfoot, yet has a high anti slip surface. It’s best suited for boats where you fish with bare feet or need extra cushioning.

Nano-DOT™ won’t get hot like traditional marine carpet, heating to only 6 degrees above the daily ambient temperature. It cleans easily with Pink Vanish Liquid from the supermarket. For those who like fishing for timid fish like bream or whiting, Nano-DOT™ will quieten activity inside the boat – such as dropping sinkers or tackle.

Nano-DOT™ comes in 2050mm x 1025mm sheets with a marine grade 3M adhesive on the back.

To remotely template your floor is easy. We request you gets some clear builders plastic from your local hardware and a sharpie pen. Put the clear plastic over the areas you want to take a template of, then draw around with your sharpie pen. You will then have a template you can put on the flooring and cut with a sharp knife. We recommend installing with 3M Primer 94 that is also available on our on-line shop.

Colours available: Winter Grey, Steel Grey, Snow Camo and Black.

Size available: 2050mm x 1025mm x 5mm.

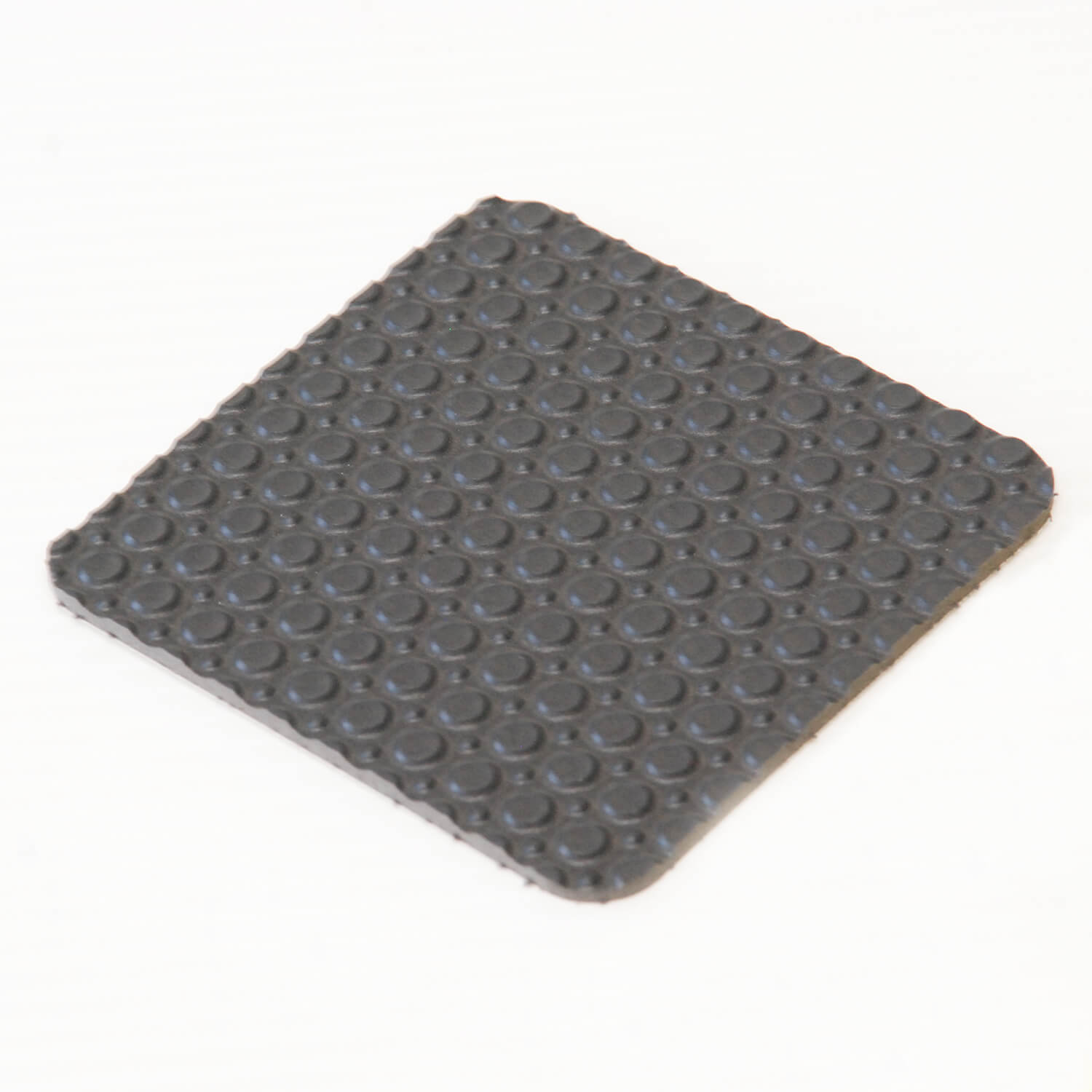

U-TREAD Octi & Z tread boat flooring

Ultralon’s U-TREAD marine decking comes in two molded patterns: Octi and Z Tread patterns. This boat flooring material is perfect for the professional fisherman or charter operator that uses their boat as a working tool. This boat flooring is a hardwearing deck tread suitable for floors, gunwales, trailers and general wet areas, improving safety and underfoot comfort when out on the water. This foam is an anti-slip, hard wearing deck tread. Available in 3mm & 5mm tread and multiple colours. If you’re looking for Boat Flooring Melbourne, Boat Flooring South Australia or Boat Flooring Tasmania, Form A Sign are able to provide you with a boat flooring price.

DIY Boat FlooringNon-Slip Pad Packs

Our Boat floor DIY packs are available in all 5 Udek colors, individually packaged and we offer free freight Australia Wide. Our 6mm thick brushed EVA, Udek boat floor DIY packs are available in Teak on Black, Winter Grey on Black, Steel Grey on Winter Grey, Steel Grey on Black & Black on Winter Grey. It has a strong 3M adhesive backing for easy application to your boat floor.

| Product | Qty | Length | Height |

|---|---|---|---|

| Large Fish Measure | 1 | 1000mm | 100mm |

| Large Non-slip Floor Pad | 2 | 1000mm | 100mm |

| Medium Non-slip Floor Pad | 2 | 380mm | 180mm |

| Small Non-slip Floor Pad | 4 | 480mm | 100mm |

| Extra Small Non-slip Floor Pad | 4 | 300mm | 100mm |

I just want my boat floor Repaired…

U-Tread Octi and Z tread is a great flooring option for the busy fisherman who just wants the job done – with Form A Sign digitally templating and installing the boat flooring;

I’m a handyman and am looking for a cheaper alternative to replace my boat floor with a DIY option. . .

DIY boat floor sheet kits are available from our shop in our Z tread & Octi Eva foam range. DIY boat flooring sheets are 2m x 1m in size. Your DIY boat flooring kit comes with 3M™ adhesive & instructions for boat floor surface preparation and boat Eva flooring installation. To work out the quantity of boat flooring sheets please use our boat flooring template below. Boat flooring rollers and 3M™ Primer 94 can also be purchased to increase the adhesion of your Eva boat flooring DIY kit. DIY boat floor kits can be couriered Australia wide.

DIY Boat Flooring - How to Template your Boat Floor

Form A Sign utilise leading global digital templating technology to improve the overall accuracy of your marine floor template. Our Prodim Proliner digital templating technology measures accurately with a wire. At the end of the wire is a metal measuring pen. With this measuring pen you can simply mark the relevant points, shaping around boat rod holders, seats, cup holders, hatches, steps, doors and curves. These points are directly translated into a digital DXF CAD file. Straight, curved and very complex shapes can be measured fast and accurate from every position.

The Proliner is the fastest, most accurate, reliable and durable digital templating solution in the market. Measuring with a wire does not require targets and has no reflection inaccuracies and therefore the Proliner gives the best return of investment to marine fabricators.

Form A Sign can digitally template boats at our Noble Park factory. Large boats that can’t be towed can also be templated on-site. If you are unable to get your boat to us to be templated, we suggest you create a paper template of your floor with sisle material (available at most hardwares) thick paper or card. Once you post this to us, we can digitally template your template. We then produce a paper pounce of the template which we send to you to check measure fit in the boat. This process continues until we have the perfect template. Once your template is finalised, we can commence the design process.

Form A Sign produce accurate digital boat flooring templates with Prodim. These templates are checked with a paper pounce to ensure they fit perfectly. We pride ourselves on having one of the tightest, best fitting boat floors available on the market.

Jet Ski Non-Slip Grip EVA Foam - U-Surf

Surf Grip features all the same benefits as U-Tread with a narrower profile and groove tread pattern making it ideal for jet skis, boats and surfboards. It is great for your boat flooring when you want a bit of bounce absorption to help protect your back or knees. You can purchase Surf Grip by the sheet and hand cut your flooring; or we can electronically template your boat and have the shapes routered.

Sheet Size

2050mm x 480mm x 5mm

Colour

Light Grey, Steel Grey and Black are in stock.

Snow Camo is for special order products.

How Do I Template For DIY Boat Flooring?

To remotely template your boat floor is easy. We request you gets some clear builders plastic from your local hardware store, sometimes called Grunt plastic, and a sharpie pen. Put the clear plastic over boat floor the areas you want to take a template of, then draw around with your sharpie pen. You will then have a template you can put on the boat flooring material. You can easily cut the boat flooring with a sharp knife. Our DIY sheets available on our on-line shop all come with boat floor installation instructions.

Boat Floor Designs

Custom artwork is included at no charge

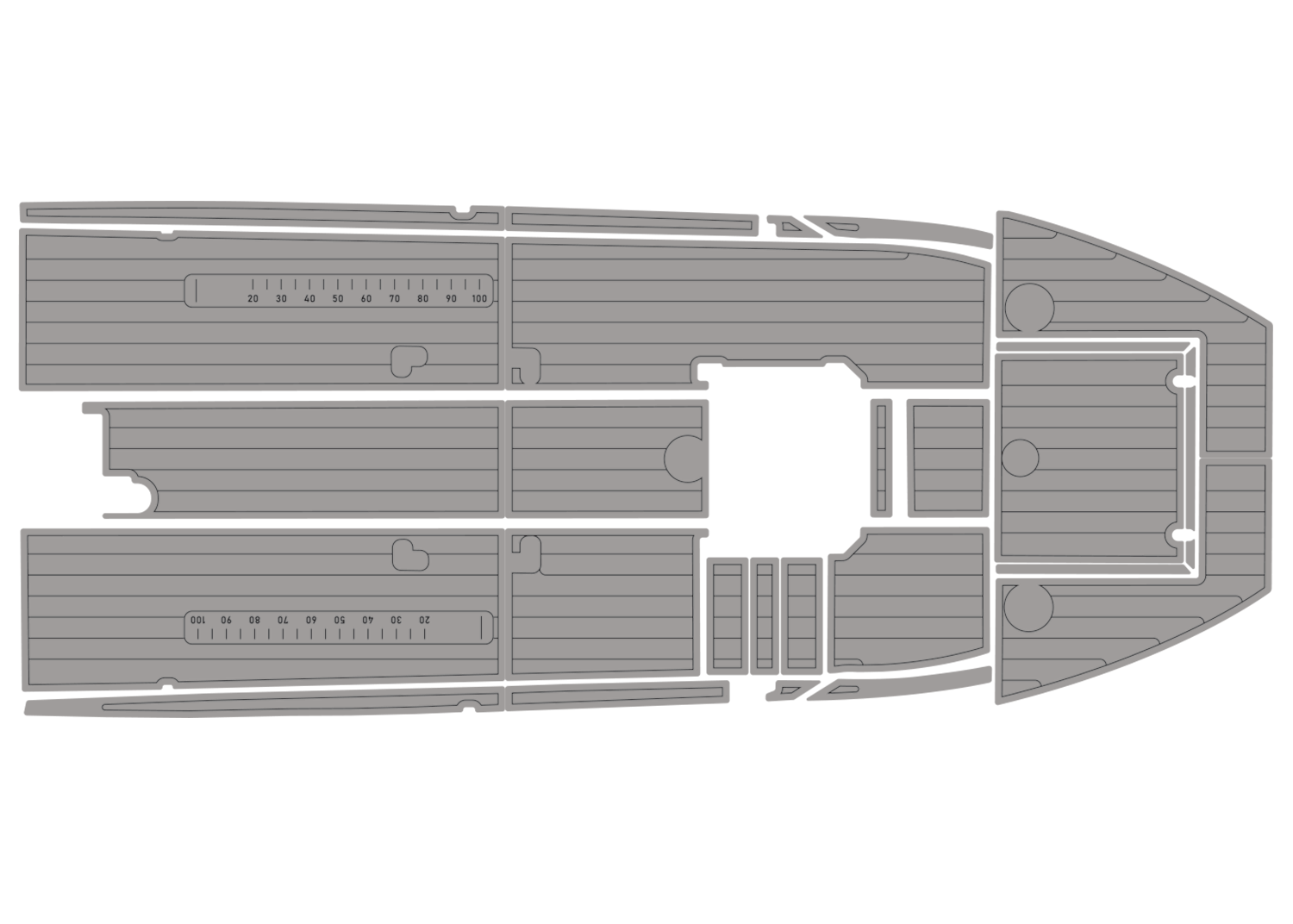

Purchasing a pre-cut kit off the shelf will likely not fit your boat as most models have different seat or rod positioning, or well thickness which all impact the tight fit of a quality boat floor. We therefore suggest all U-DEK boat floors are templated at check the fit.

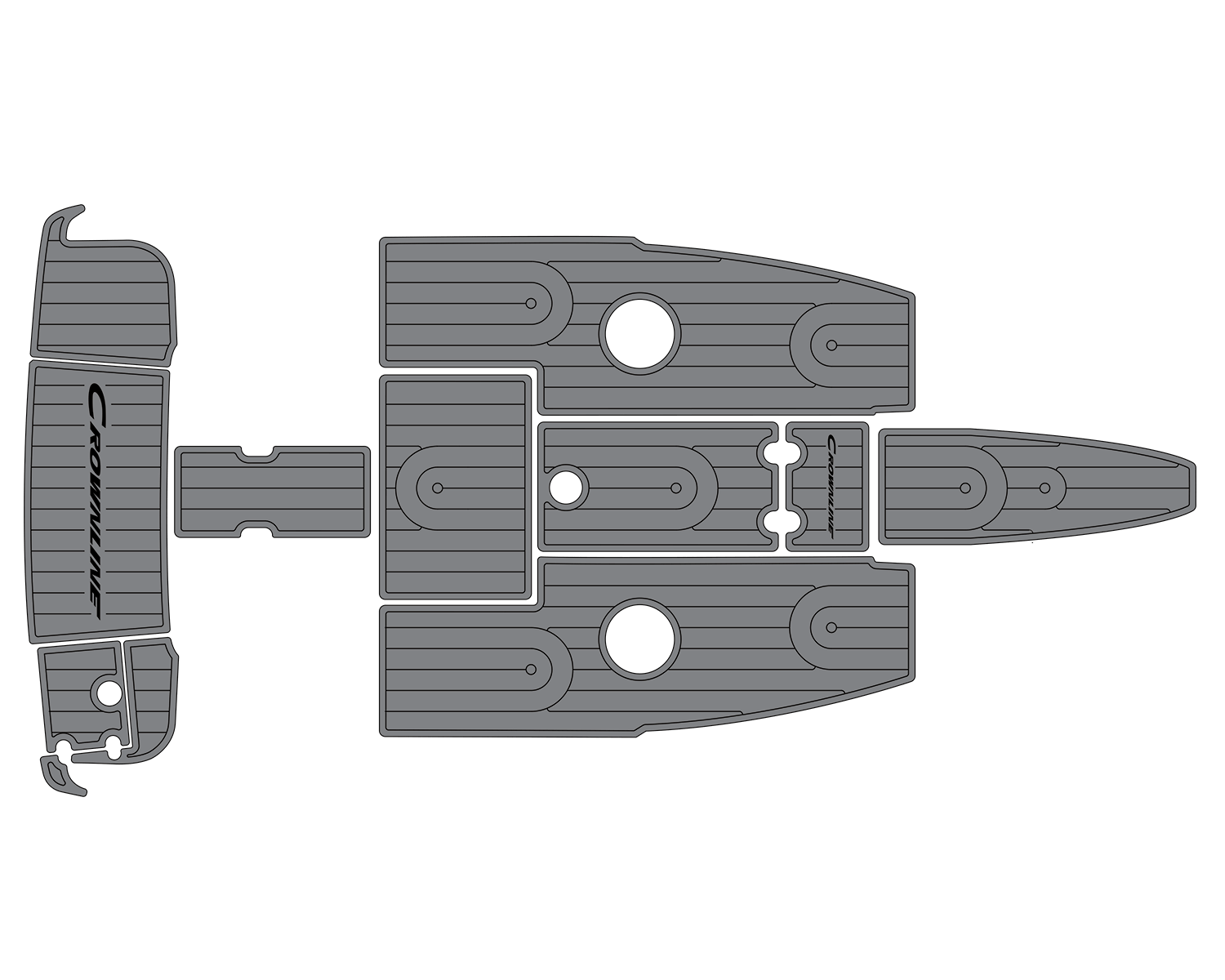

U-DEK Four Winns Swim Deck

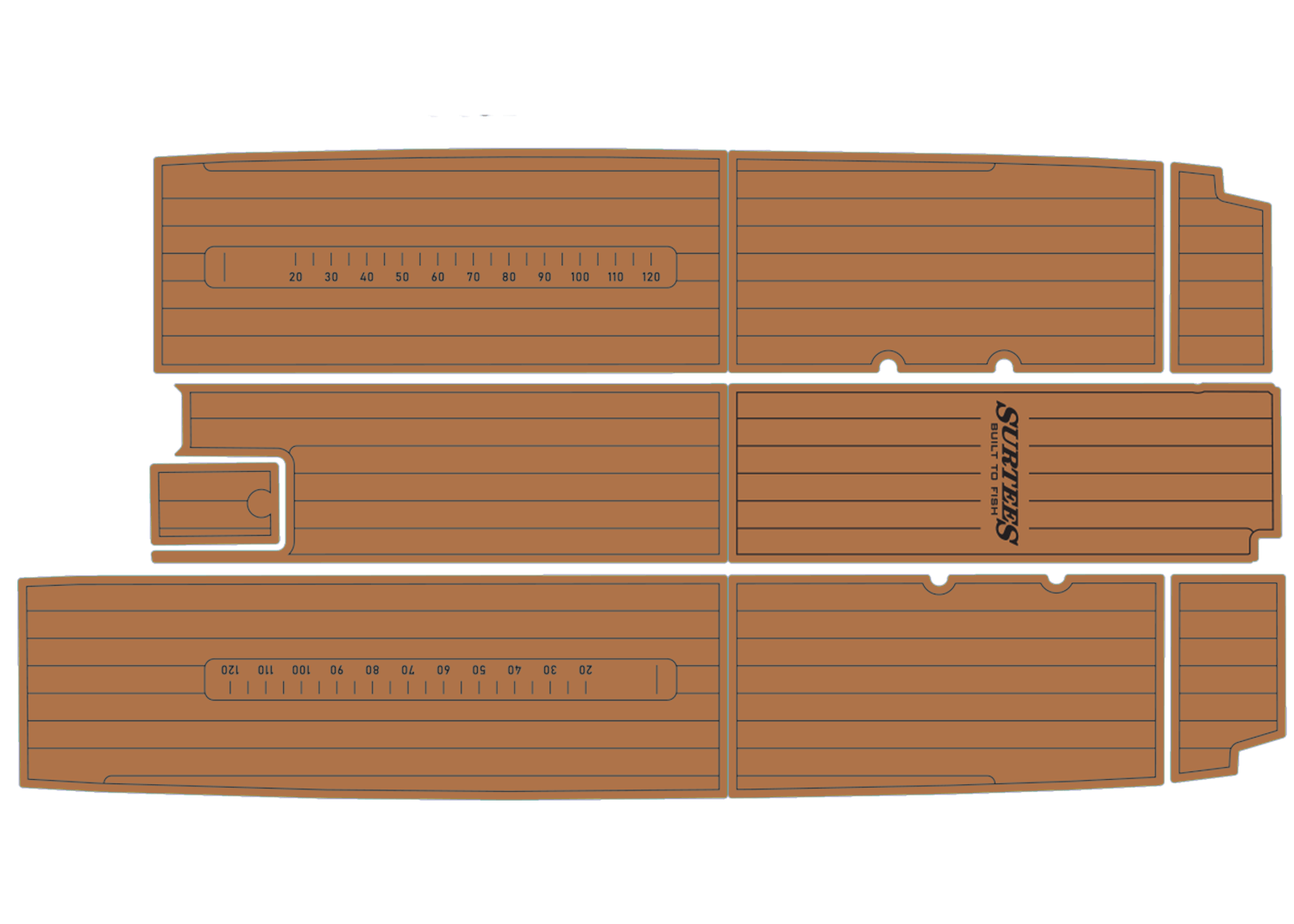

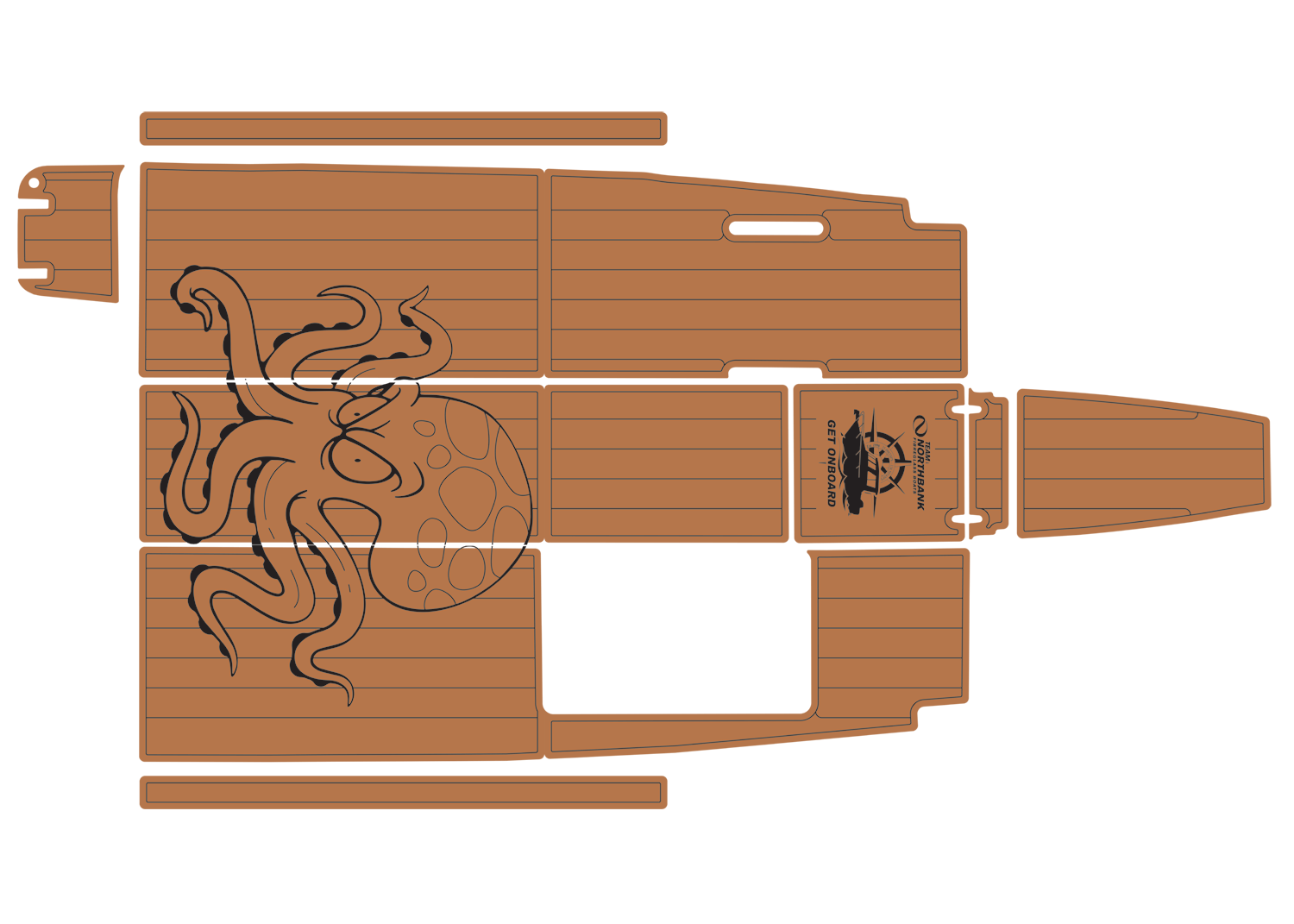

U-DEK Atomix Kraken and Fish Measures

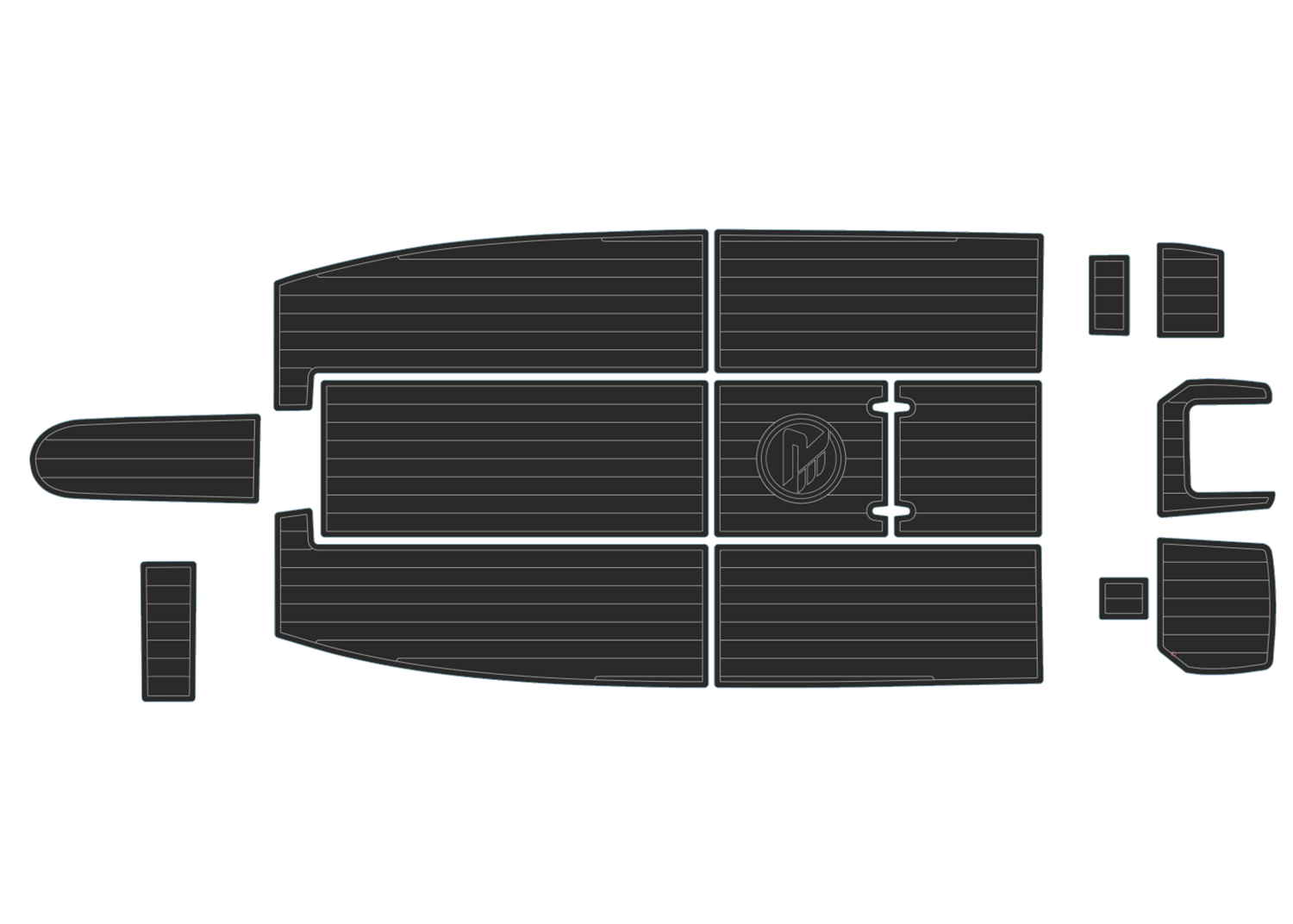

U-DEK Barcrusher Teak on Black

U-DEK Bass Straight Winter Grey on Black with Marlin rout

U-DEK Brig Inflatable, Winter Grey on Black

U-DEK Centurion Winter Grey on Black Swim Deck

U-DEK McLay 611 SC Fatboy, Winter Steel and Nano-Dot Combo

U-DEK Bombs Away, Winter Grey on Black

U-DEK Stabicraft, Flathead in Winter Grey on Black

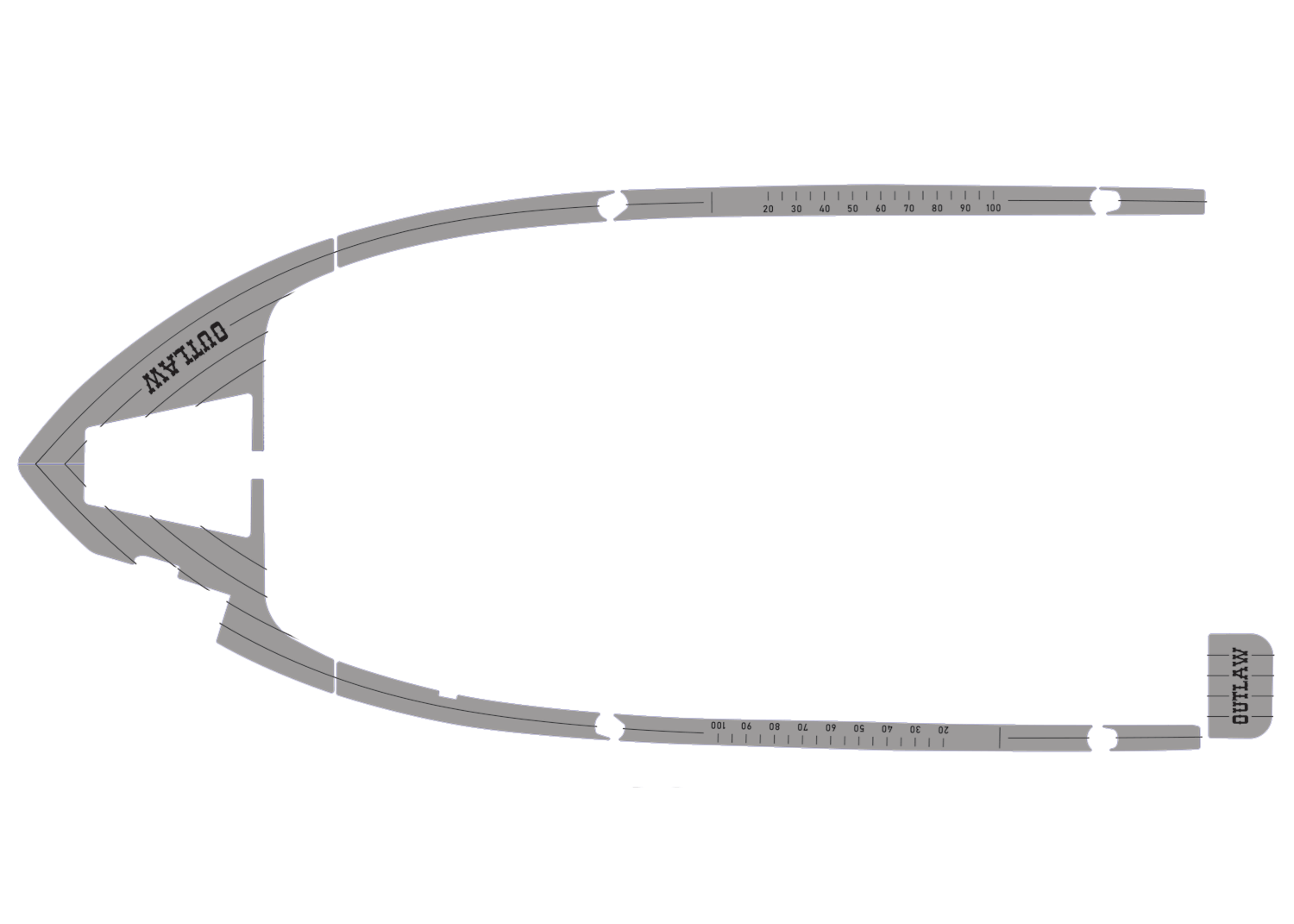

U-DEK Grady-White, Teak on Black with Fish Measures

U-DEK Triton Boats, Diagonal Pattern, Winter Grey on Black

U-DEK Killer Moon lasered logo and Fish Measures, Winter Grey on Black

U-DEK Malibu logo Swim Deck, Winter Grey on Black

U-DEK Eagle lasered in Winter Grey on Black

U-DEK Merryfisher, All Riviera in Teak on Black

U-DEK Boards Pattern, Winter Grey on Black

U-DEK Barcrusher Baitfish rout and laser, Winter and Steel Grey on Black

U-DEK Bass Straight Winter Grey on Black with Marlin rout

U-DEK Caribbean rout and lasering, Winter Grey on Black

U-DEK Chaparral in Steel and Winter Grey on Black

U-DEK McLay 611 SC Fatboy, Winter Steel and Nano-Dot Combo

U-DEK Bombs Away Roof, Black on Winter Grey

U-DEK Edencraft, Winter Grey on Black

U-DEK Four Winns, Teak on Black

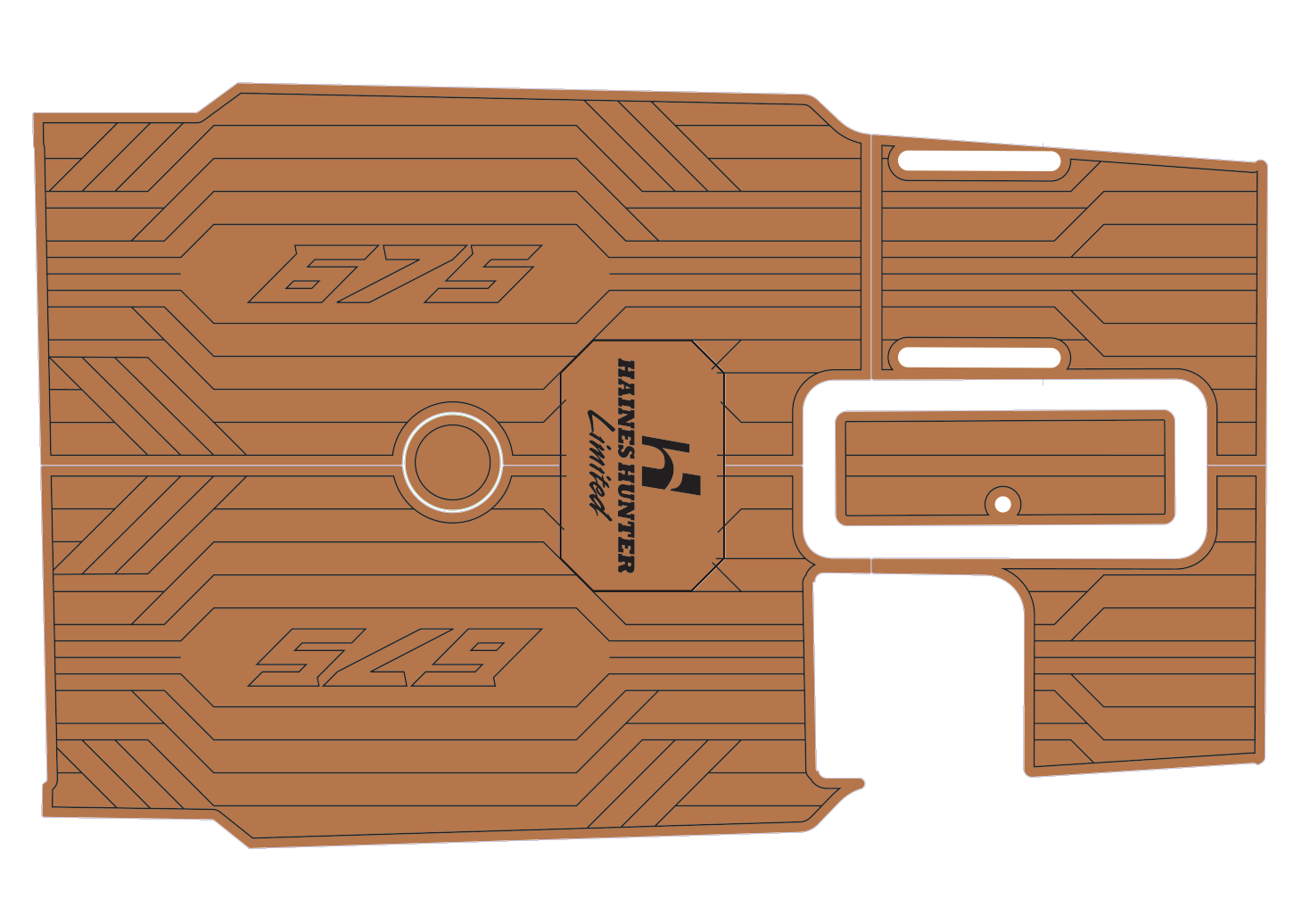

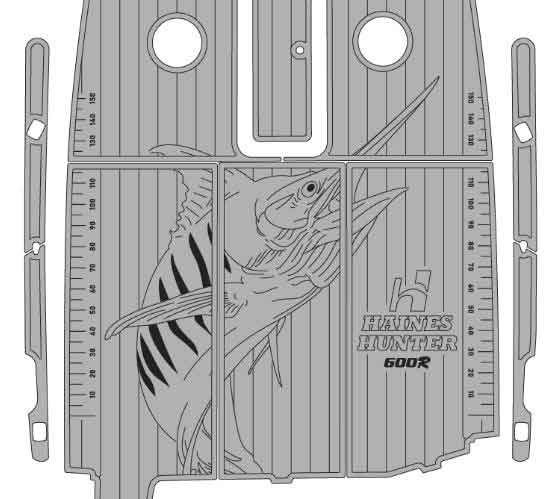

U-DEK Haines Hunter, Winter Grey on Black

U-DEK Harris Crown Pontoon, Quilt Pattern in Teak on Black

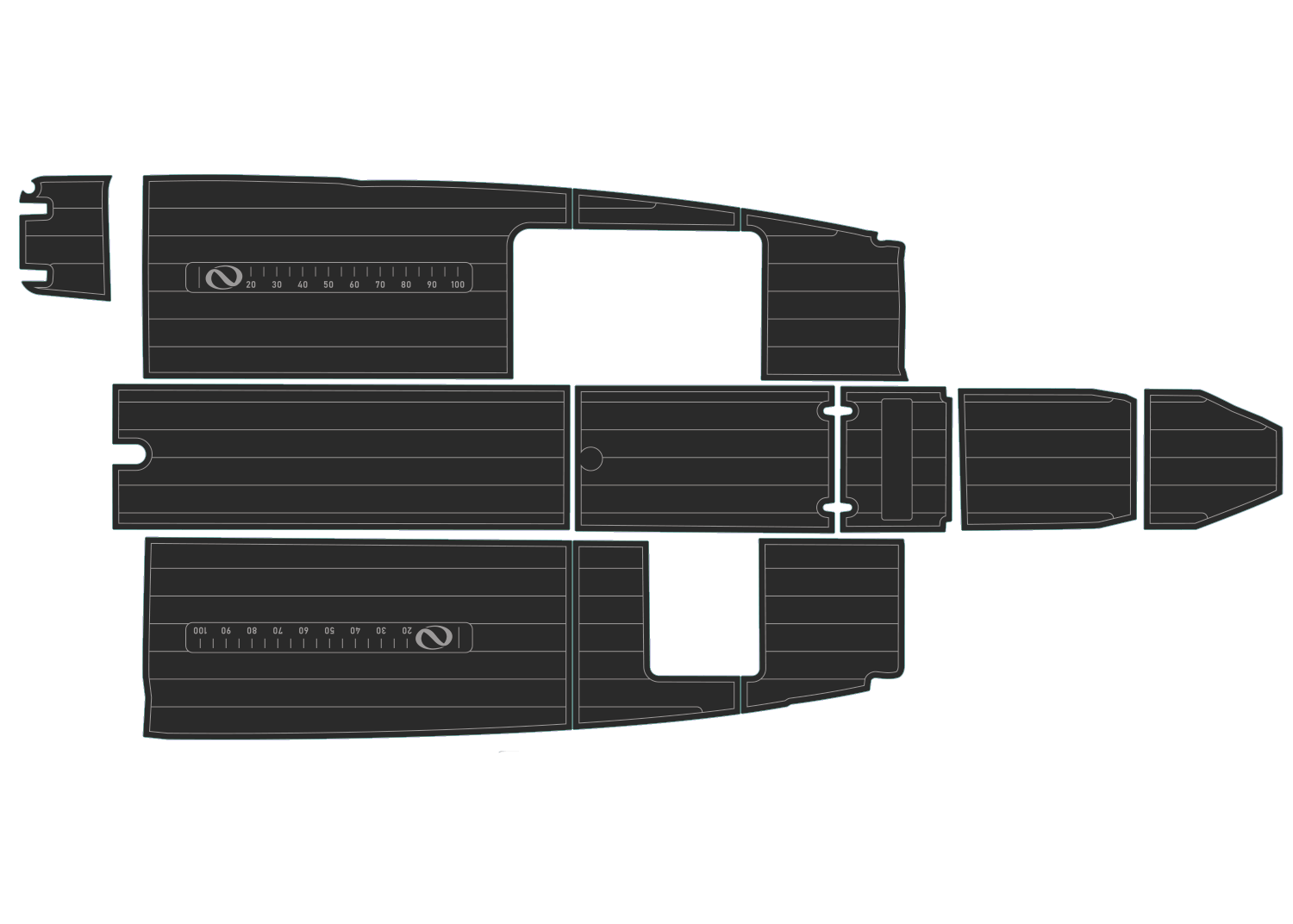

U-DEK Kill Bill and Fish Measures, Winter Grey on Black

U-DEK Savage Boats, Kracken Skull, Winter Grey on Black

U-DEK McClay with Kenwood Truck routed into Winter Grey on Black

U-DEK McClay with Kenwood Truck routed into Winter Grey on Black

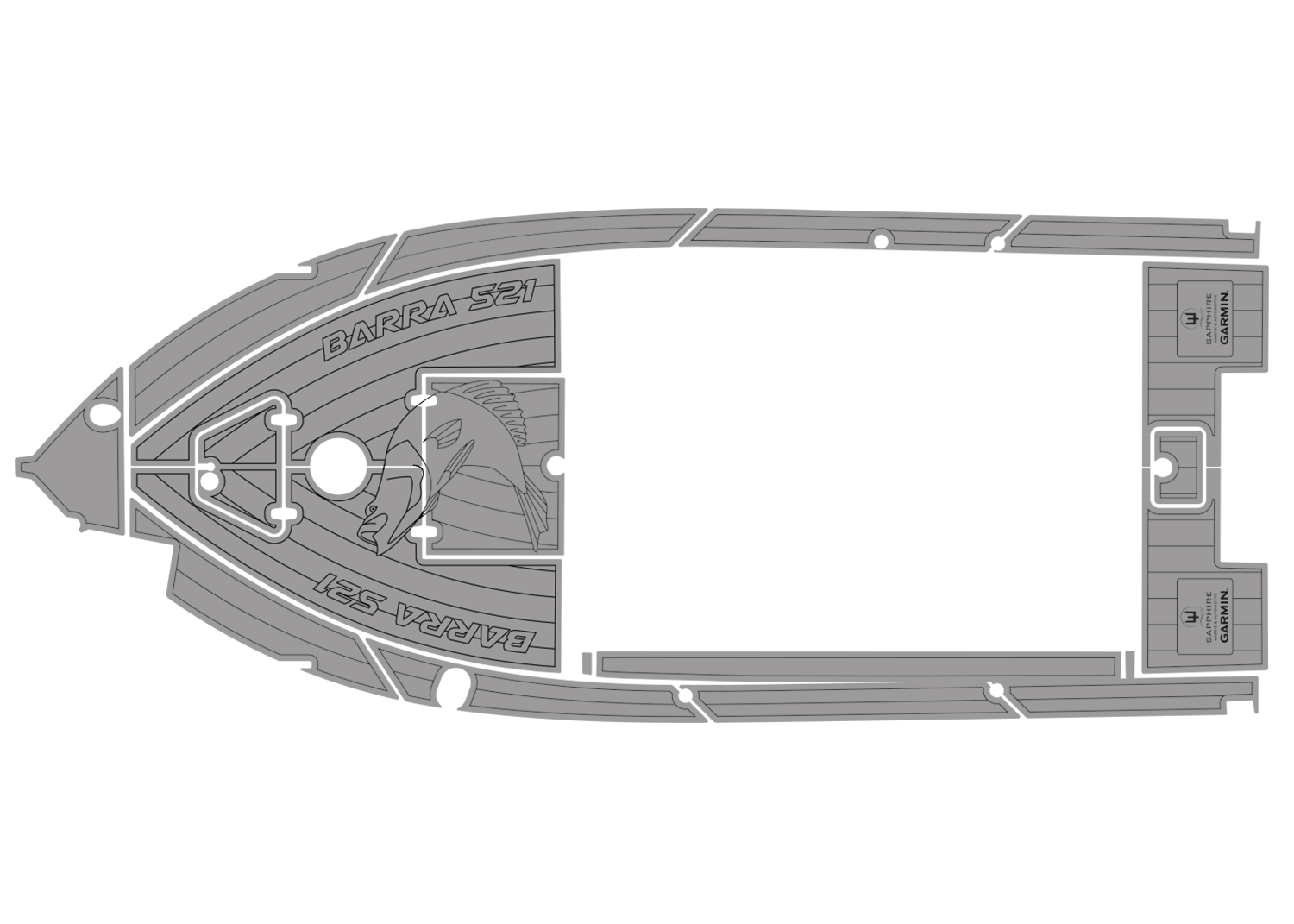

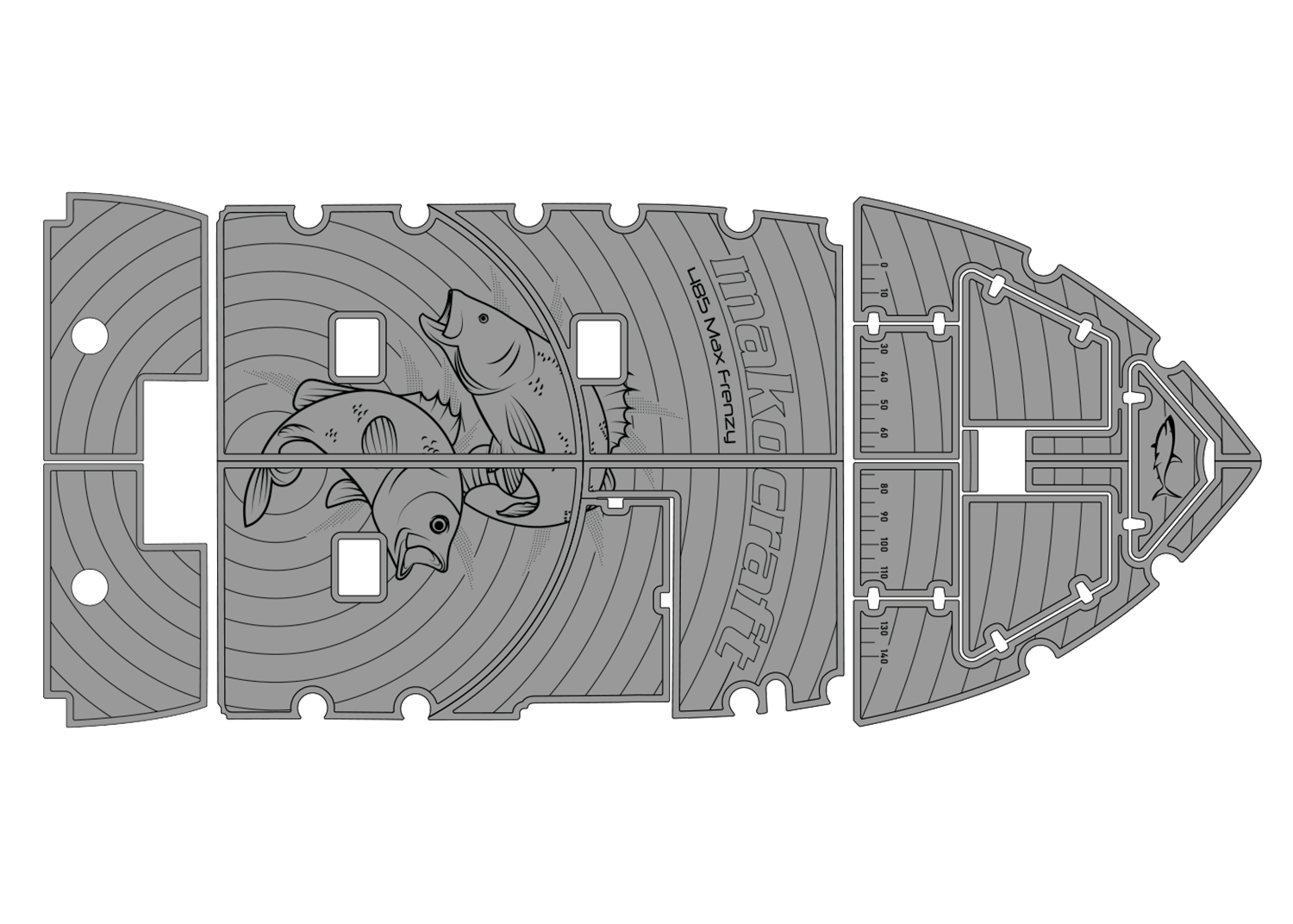

U-DEK Mako Craft, custom rout and lasering

U-DEK Barcrusher Boards Pattern in Steel on Winter Grey

U-DEK Barcrusher Custom Barra Swirl

U-DEK Bayliner Winter Grey on Black

U-DEK Barcrusher, Winter Grey on Black

U-DEK Winter Grey on Black Curve Boards Pattern

U-DEK Mustang, rout and lasering Teak on Black

U-DEK Evolution Boats, Teak on Black

U-DEK Glastron, Winter and Steel Grey on Black Combo

U-DEK Haines Hunter, Marlin and Fish Measures

U-DEK Hornet White Pointer, Steel Grey on Black

U-DEK Lone Star Marine, Winter Grey on Black

U-DEK Malibu Swim Deck, smash effect logo, Steel Grey on Winter Grey

U-DEK McLay Octopus and Fish Measures in Winter Grey on Black

U-DEK Merv Hughes moustache lasered

U-DEK Captain Silver and Fish Measure

U-DEK Barcrusher Southern Cross and Fish Measures, Black on Winter Grey

U-DEK Bass Cat Custom Nano-Dot Logo

U-DEK Boston Whaler Teak on Black

U-DEK Caribbean rout and lasering, Teak on Black

U-DEK McLay 611 SC Fatboy, Winter Steel and Nano-Dot Combo

U-DEK Ocean Runner, Winter Grey on Black

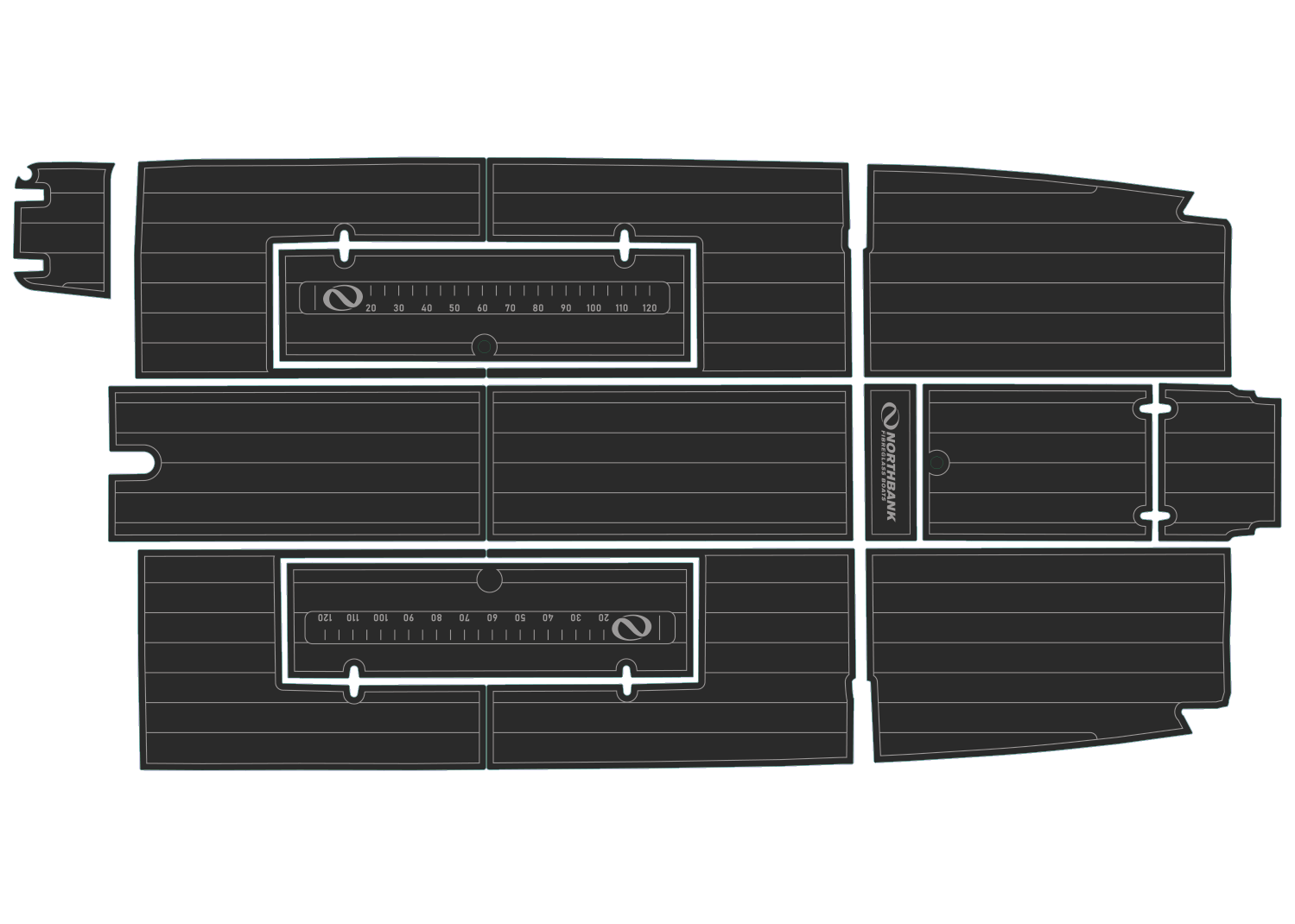

U-DEK Northbank, Mustang and Stacer

U-DEK Extreme, Winter Grey on Black with Marlin rout

U-DEK Glastron, Winter and Steel Grey on Black Combo

U-DEK Haines Hunter, Floor and Fish Measure in Winter Grey on Black

U-DEK Hornet White Pointer, Winter Grey on Black

U-DEK Jeanneau logo and Fish Measure, Teak on Black

U-DEK Malibu logo on Swim Deck, Steel Grey on Winter Grey

U-DEK McLay Barra 551 Fotress with Black on Winter Grey

U-DEK Papa Smurf and Fish Measure in Winter Grey on Black

U-DEK Australian Plate Alloy, black on Winter Grey

Custom designed boat floors

Digital Drawings

purchase your DIY boat flooring PACKS

Shop Here

Premium Custom Logos

Every fisherman likes impressive shiny rods, reels and tackle. Why not impress your mates with a premium custom logo in your floor? Our professional designers can personalise your boat floor with router engraved custom decking lines, fish measures, boat names, boat brands and more for that professional yet unique customised look.

If your logo is more detailed or requires a sleek modern finish, then a lasered logo on your boat flooring may be the perfect option for you.

Form A Sign keep up to date with the latest laser and router technology to ensure your routed or lasered boat flooring will be quality, and made to last.

The best bit is that there are no additional costs for including premium custom logos in your boat floor. All boat floor customised design, routering and lasering is included within your standard boat floor kit.

How to clean your Ultralon marine Flooring

Care

The easiest way to clean your decking is to use a high pressure hose 1 foot distance away from the decking. For stubborn stains follow below.

STEP 1:To clean dirt, etc. from your decking, use U-Dek Cleaner and water along with a medium bristled deck brush. Spray directly on a cool surface and not in direct sunlight. Lightly move around the cleaner with a soft or hard bristle brush. Let sit for 15-30 seconds. Add a small amount of water to the surface and lightly scrub again before rinsing. Repeat if necessary. This cleaner is also safe to use on upholstery and carpet.

STEP 2:To remove suntan lotion, use the U-Dek Cleaner alone with a medium bristled deck brush. Put a small amount of the U-Dek Cleaner on the stain. Dip a medium bristled boat brush in warm water and work around until the oil comes out. Rinse with water. Repeat if needed.

STEP 3: To remove rust stains, use a cap full of Grunt Cleaner. Apply on the rust stain and allow to soak for 3-5 minutes. If necessary, use latex/nitrile gloves to massage the cleaner into the brushed or embossed texture of the decking. Rinse with water. Repeat if necessary, the rust stain will eventually be removed. With Grunt cleaner, please be careful to avoid getting this solvent on the sides of the decking, it could damage the lamination or PSA. Please be careful with all other cleaning products. Wear vinyl or nitrile gloves and eye protection.

DO NOT USE

• Mineral Spirits

• Grunt Cleaner (not as a general cleaner, okay for Step 3 application only)

• Acetone (if it must be used, avoid the adhesives as best as possible)

• Bleach (if used, dilute 1:1 with water)

For best cleaning results, tend to all stains, spills and leaks as soon as possible

Situations to Avoid

Long-term storage of items on the decking such as inflatable pool toys, tools or water bottles. Keep decking away from reflective surfaces or from under glass. These objects can refract/reflect light, thereby concentrating the beams to a level which can be destructive to the decking.

Clean spills and messes on the decking immediately to reduce possible staining. Some materials can stain the decking if not promptly removed. Examples include: mustard, ketchup, fish hooks left to rust, fish blood, bird droppings, etc.

Light Amplification

Light amplification can occur when there is an intensification of sunlight throughmagnification, reflection, or refraction. This includes, but is not limited to, situations where there is a highly reflective surface such as stainless hardware, high gloss white gel coat or aluminium.

SITUATIONS TO AVOID

When installing U-DEK®, avoid areas around vertical reflective surfaces and glossy/shiny hardware. Do not leave inflatable pool toys or water bottles stored long-term ontop of U-DEK® or placed near reflective surfaces or beneath glass as detailed in Section II in the U-DEK® warranty. These objects can refract/reflect light, thereby concentrating the beams to a level which can be destructive to the U-DEK® pad/panel.

While U-DEK® is a durable product, it is recommended that reducing the exposure to elements, when not in use, will help extend the life of your decking and reduce colour fade.

LIGHT AMPLIFICATION ACROSS DIFFERENT SURFACES

BOATS WITH GEL COAT SURFACES

The sun can reflect off gel-coat surfaces to damage the U-DEK® product. High gloss white and concave curves are particularly susceptible to light amplification.

For certain applications and under certain conditions, U-DEK® applied in the cockpit and other areas with vertical surfaces and/or reflecting off hardware/stainless, etc.

This can leave U-DEK® exposed to operational temperatures above 80°C (176°F).

PLATE & ALUMINIUM BOATS

Lighter colors reduce the light amplification problem. However, it will not be covered under our standard warranty* if Light Amplification occurs.

Other manufacturing defects will still be covered under our standard warranty.

*Please refer to the U-DEK® warranty for more information

PLATE & ALUMINIUM BOATS

Light amplification is very rare in plate and aluminium boats. Mainly due to glass doors/windscreens/windows or the like and gloss white paint.

Good practice is to offset U-DEK® pads 15mm minimum from welds (particularly on platforms, next to walls):

- Allows for better drainage

- Stops water pooling on U-DEK® pad (which magnifies the heat)

- Provides safety margin for light reflected of wall panel (misses the U-DEK® panel)

When installing U-DEK®,additional ‘mitigating’ panelscan be installed to lessen the risk of light amplification.

After installation, the preferred method of storage is that the boat (or any other surface of application) be covered.

U-DEK® pads are very durable, but they will last longer and the colors will fade more slowly if they are not exposed to the elements when not in use.

Examples include keeping the boat; in a garage, covered with a canvas boat cover, in a covered boat slip, etc.

Boat Flooring Installation Instructions

TOOLS required:

- Sharp razor knife

- Isopropanol or mentholated spirits cleaner (preferred)

- 25mm/1 Inch Masking Tape

- Roller (preferred)

- 3M Primer 94 (option for areas that will not have 100% adhesion)

- 3M Edge Sealer (option for areas exposed to water regularly)

STORAGE:

Ultralon Decking should be stored in a cool, dry, indoor location until installed on your boat.

IMPORTANT INSTALLATION CONSIDERATION:

Do NOT install decking in temperatures below 15˚C (60˚F) or above 25˚C (77˚F)

Do NOT attempt to remove or adjust placement once decking has adhered.

Check fuel vapor from the floor prior to installation as this will effect adhesives.

Check new fiberglass floors that all fiberglass mold release agents are removed (speak to your boat manufacturer regarding removal.)

If your fiberglass boat is older and chalky in appearance, clean with a deoxidizer prior to installation.

Ensure floors are clean of all contaminates prior to installation, eg oil, fuel, polish etc.

PREPARATION :

1. Thoroughly clean the surface area where decking will be applied using an alcohol based cleaner, such as Isopropanol.

2. Make sure all grease, adhesive, mold-release, wax and other substances are removed before installing the product. The area must be completely dry before applying decking.

3. Use a rag to apply a thin coat of 3M Primer 94 to the templated area on the hull. This product increases the 3M adheision.

INSTALLATION :

1. Before you peel back the adhesive backing, place the decking on the application surface to check correct fit and spacing and determine the exact location of the decking.

2. Turn decking over so that the adhesive backing is face up. With a sharp razor knife carefully cut the adhesive paper backing down the center at the shortest width. Be sure to completely cut through the backing paper WITHOUT cutting the decking.

3. Now peel back and fold the four corners of the paper backing.

4. Turn the decking back over and position it exactly where you want it installed.

5. Using the 25mm/1 inch masking tape, tape one side of the decking in position on the application surface. Taping prevents the decking from moving while installing.

6. Then carefully lift up the side that is not taped down and pull up the folded corners to loosen the adhesive backing.

7. From the center working towards the outer edges, slowly and carefully peel the rest of the paper backing while applying the decking. Apply even pressure with a roller over the decking to ensure there’s a firm bond between the decking and the surface area. A Roller will apply the required 2kg of pressure per square inch of decking. Roll in all directions to ensure adhesion.

DO NOT PULL OR STRETCH THE DECKING.

8. Remove the masking tape from the other side of the decking and repeat step 7.

9. The Pressure-Sensitive Adhesive (PSA) must be firmly rolled and pressed down on all surface areas and edges of the decking to ensure there’s uniform adhesion.

10. If required 3M Edge sealer will secure the edge of your decking glue. Place masking tape around the top of your decking product. Use a small paint brush or applicator to put a thin line of 3M edge sealer around the outside glued edge of your decking. Once dry, remove the masking tape. Do not allow the edge sealer to come into contact with the top face of your decking product.

GALLERY

What do our customers say?

“I’ve just returned from 6 weeks in The Territory, red dust mud you name it and the U-DEK has come up like new with a bit of a scrub using Vanish laundry detergent. Honestly it looks as good as new. I can’t recommend this flooring enough. It even stayed cool under foot in the territory heat. U-DEK is the best decision we have made for the boat. We just love it!!”

DAVE SILVA

Wilson Fishing

“Hey guys! Just wanted to say that your U-DEK U-Tread Octi is without a doubt the best flooring product on the market. I have had it fitted to my charter vessel for just over three years. If you need an ambassador for your product I would be happy to stand by it. I own and operate Wild Hinchinbrook Adventures and get plenty of questions about the flooring, it just stands up to the day in day out punishment.”

BEN WESTON

“Highly recommend Form A Sign Australia, nothing but great service and quality workmanship!!

They did an excellent job in putting my design together, no problems at all editing and shifting to get it right and i couldn’t be happier with the finished product!

Cheers.”